| 1 |

GWEC. Global wind report 2022[R]. GWEC, 2022.

|

| 2 |

许经纬. 碳纤维/玻璃纤维混杂增强复合材料力学性能研究及风电叶片应用[D]. 苏州: 苏州大学, 2019: 4–5.

|

|

XU Jingwei. Study on mechanical properties of carbon fiber/glass fiber hybrid reinforced composites and application of wind turbine blades[D]. Suzhou: Soochow University, 2019: 4–5.

|

| 3 |

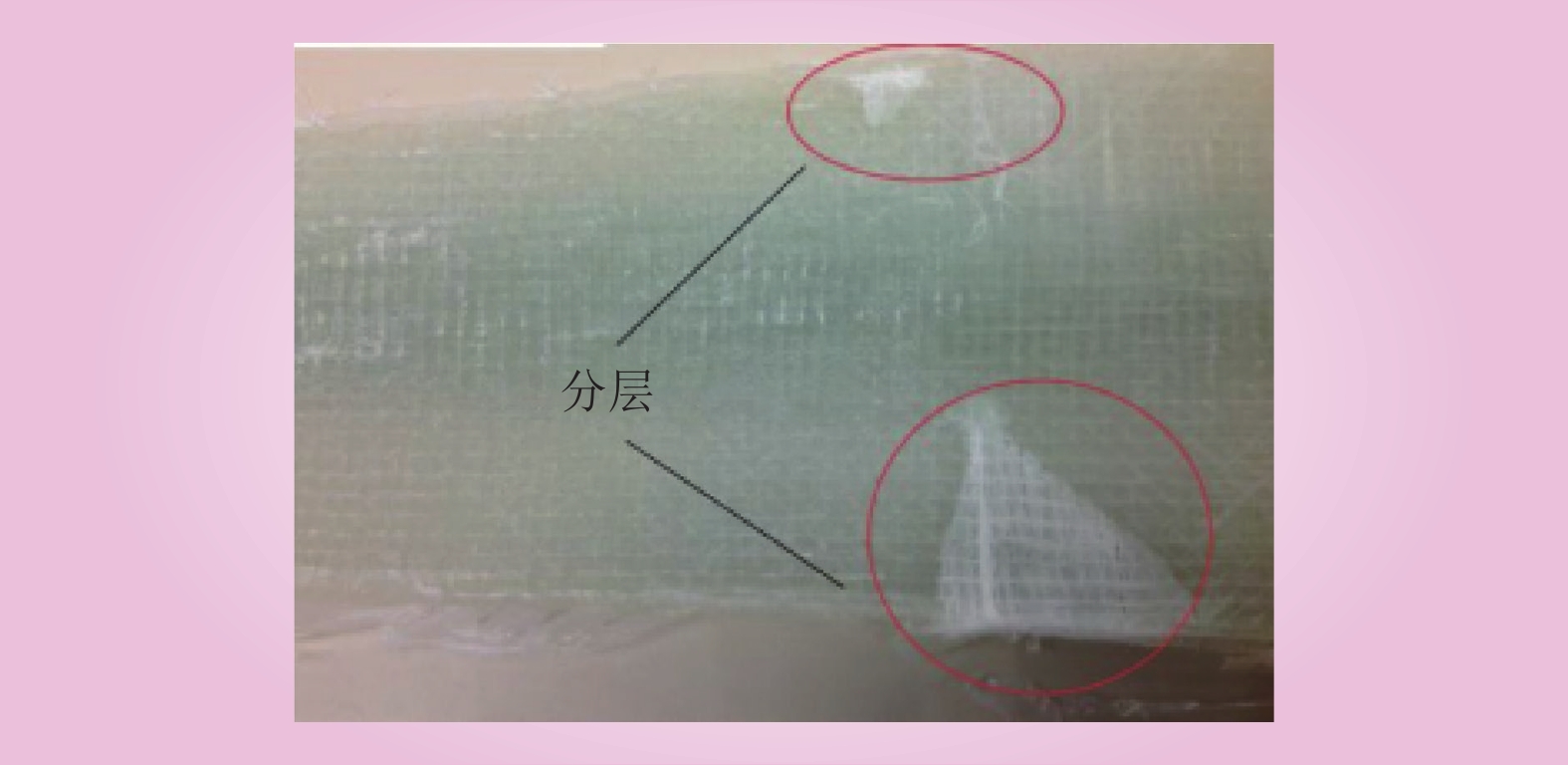

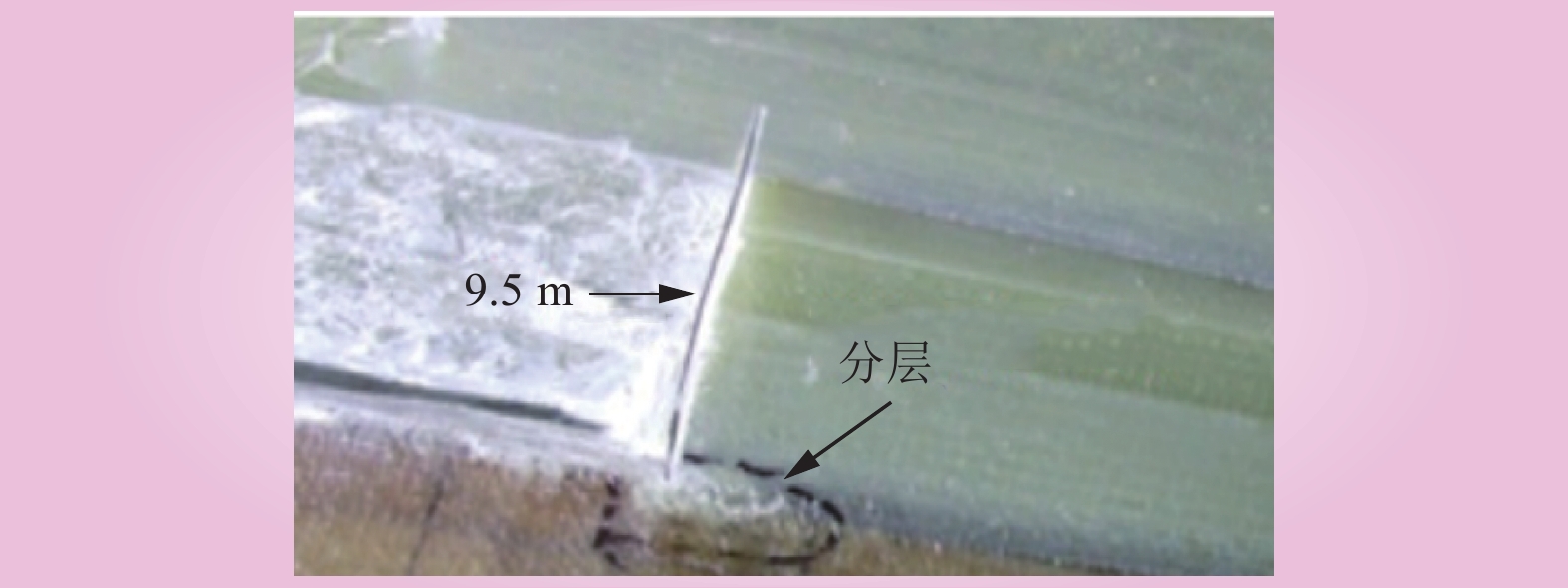

李亚娟. 风电叶片分层缺陷演化的力学行为及声发射响应特性研究[D]. 保定: 河北大学, 2015: 8–9.

|

|

LI Yajuan. Study on mechanical behavior and acoustic emission response characteristics of delamination defect evolution of wind turbine blades[D]. Baoding: Hebei University, 2015: 8–9.

|

| 4 |

HABIBI H, CHENG L, ZHENG H T, et al. A dual de-icing system for wind turbine blades combining high-power ultrasonic guided waves and low-frequency forced vibrations[J]. Renewable Energy, 2015, 83, 859- 870.

|

| 5 |

ZHAO Q, YUAN Y P, SUN W L, et al. Reliability analysis of wind turbine blades based on non-Gaussian wind load impact competition failure model[J]. Measurement, 2020, 164, 107950.

|

| 6 |

CHEN X F, YAN R Q, LIU Y M. Wind turbine condition monitoring and fault diagnosis in China[J]. IEEE Instrumentation & Measurement Magazine, 2016, 19 (2): 22- 28.

|

| 7 |

SEYR H, MUSKULUS M. Decision support models for operations and maintenance for offshore wind farms: a review[J]. Applied Sciences, 2019, 9 (2): 278.

|

| 8 |

赵元星, 汪建文, 张立茹, 等. 气动力和离心力对风力机叶片应力影响研究[J]. 太阳能学报, 2021, 42 (2): 225- 232.

|

|

ZHAO Yuanxing, WANG Jianwen, ZHANG Liru, et al. Research on influence of aerodynamic load and centrifugal load on wind-turbine-blade stress[J]. Acta Energiae Solaris Sinica, 2021, 42 (2): 225- 232.

|

| 9 |

国防科学技术委员会. GJB1038.1A—2004:纤维增强复合材料无损检验方法第一部分超声波检验[S]. 北京: 中国标准出版社, 2004.

|

| 10 |

国防科学技术委员会. GJB1038.2A—2004:纤维增强复合材料无损检验方法第二部分X射线照相检验[S]. 北京: 中国标准出版社, 2004.

|

| 11 |

中华人民共和国航天工业部.QJ 1274—1987:玻璃钢层压板超声波检测方法[S].

|

| 12 |

中华人民共和国航天工业部. QJ 2914—1997:复合材料结构声发射检测方法[S].

|

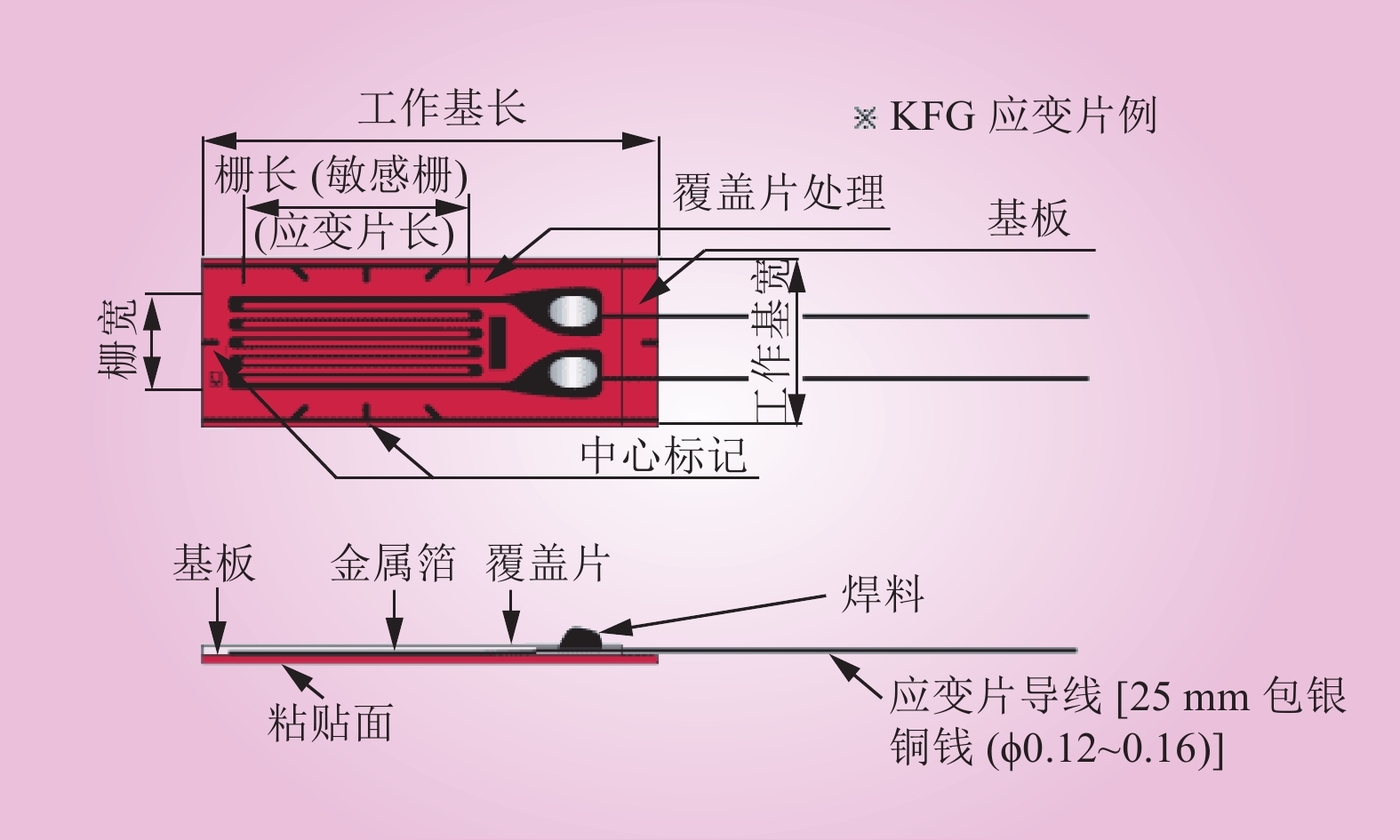

| 13 |

美国材料与试验协会. ASTM E1495/E1495M-2012:复合材料层压板和胶接接超声检测标准指南[S].

|

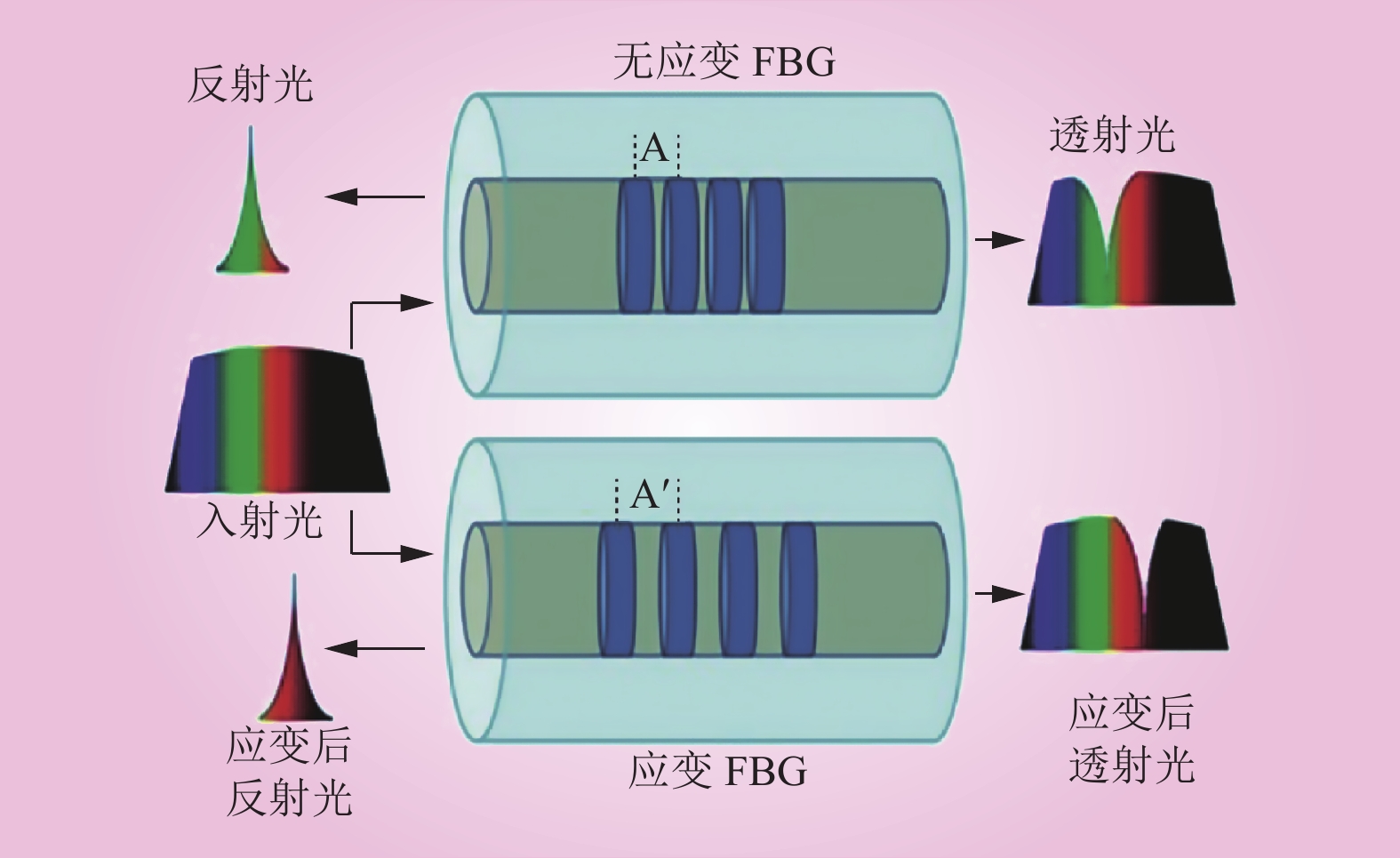

| 14 |

美国材料与试验协会. ASTM E1888/E1888M-2007:带巴沙(Balsa)木芯的玻璃纤维增强塑料压力容器的声发射检验的标准规程[S].

|

| 15 |

中国可再生能源学会风能专业委员会. 2012年全国风电设备运行质量调查概述[J]. 风能, 2013(9): 36–44.

|

|

The Wind Energy Professional Committee of the Chinese Renewable Energy Society. Overview of the 2012 national wind power equipment operation quality survey [J]. Wind Energy, 2013 (9): 36–44.

|

| 16 |

乌建中. 风电叶片全尺寸结构测试理论基础、系统设计和试验方法[M]. 上海: 同济大学出版社, 2021: 1.

|

| 17 |

李德源, 叶枝全, 陈严, 等. 风力机叶片载荷谱及疲劳寿命分析[J]. 工程力学, 2004, 21 (6): 118- 123.

|

|

LI Deyuan, YE Zhiquan, CHEN Yan, et al. Load spectrum and fatigue life analysis of the blade of horizontal axis wind turbine[J]. Engineering Mechanics, 2004, 21 (6): 118- 123.

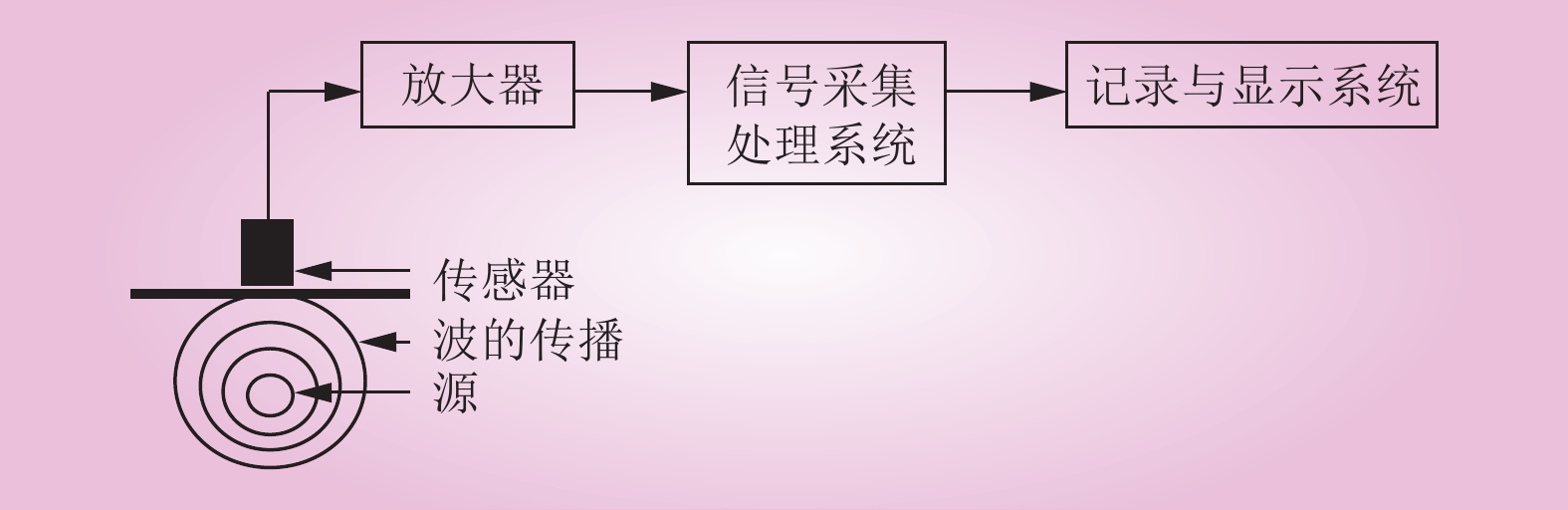

|

| 18 |

周伟, 张洪波, 马力辉, 等. 风电叶片复合材料结构缺陷无损检测研究进展[J]. 塑料科技, 2010, 38 (12): 84- 86.

|

|

ZHOU Wei, ZHANG Hongbo, MA Lihui, et al. Advances in non-destructive testing of structures defects for wind turbine blade composite material[J]. Plastics Science and Technology, 2010, 38 (12): 84- 86.

|

| 19 |

NAGLE A J, DELANEY E L, BANK L C, et al. A comparative life cycle assessment between landfilling and co-processing of waste from decommissioned Irish wind turbine blades[J]. Journal of Cleaner Production, 2020, 277, 123321.

|

| 20 |

KURBATOVA A S, BASHKIN V N. Urban landscapes and streaming structures as a basis of urban construction planning[J]. Management of Environmental Quality:an International Journal, 2006, 17 (2): 184- 196.

|

| 21 |

AL KATSAPRAKAKIS D, PAPADAKIS N, NTINTAKIS I. A comprehensive analysis of wind turbine blade damage[J]. Energies, 2021, 14 (18): 5974.

|

| 22 |

Defect types and mechanism of wind turbine blades[EB/OL]. (2022-09-28)[2022-11-15]. https://encyclopedia.pub/entry/27751.

|

| 23 |

风机叶片在台风中结构破坏的分析_全球新能源网[EB/OL]. (2006-05-22)[2022-11-15].https://www.xny365.com/news/article-125468-4.html.

|

| 24 |

HASELBACH P U, BITSCHE R D, BRANNER K. The effect of delaminations on local buckling in wind turbine blades[J]. Renewable Energy, 2016, 85, 295- 305.

|

| 25 |

ZHOU H F, DOU H Y, QIN L Z, et al. A review of full-scale structural testing of wind turbine blades[J]. Renewable and Sustainable Energy Reviews, 2014, 33, 177- 187.

|

| 26 |

AL-KHUDAIRI O, HADAVINIA H, LITTLE C, et al. Full-scale fatigue testing of a wind turbine blade in flapwise direction and examining the effect of crack propagation on the blade performance[J]. Materials, 2017, 10 (10): 1152.

|

| 27 |

白学宗, 安宗文, 侯运丰, 等. 低速冲击载荷下的风电叶片刚度退化规律[J]. 太阳能学报, 2022, 43 (1): 132- 139.

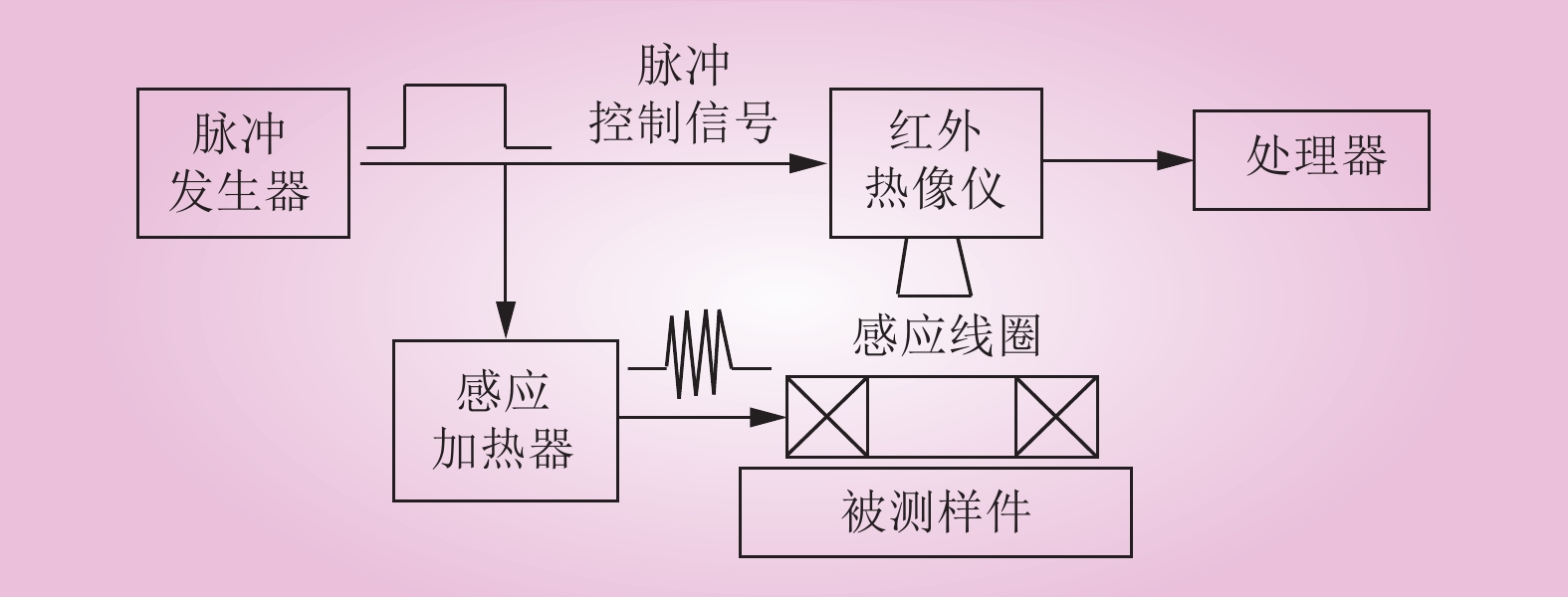

|

|

BAI Xuezong, AN Zongwen, HOU Yunfeng, et al. Stiffness degradation rule of wind turbine blade under low-velocity impact load[J]. Acta Energiae Solaris Sinica, 2022, 43 (1): 132- 139.

|

| 28 |

RAVIKUMAR K, SUBBIAH R, RANGANATHAN N, et al. A review on fatigue damages in the wind turbines: challenges in determining and reducing fatigue failures in wind turbine blades[J]. Wind Engineering, 2020, 44 (4): 434- 451.

|

| 29 |

江苏省风力发电机叶片分析鉴定[EB/OL]. (2012-09-17)[2022-11-15]. http://falab.com.cn/case-3/100.html.

|

| 30 |

AMIRZADEH B, LOUHGHALAM A, RAESSI M, et al. A computational framework for the analysis of rain-induced erosion in wind turbine blades, part I: stochastic rain texture model and drop impact simulations[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2017, 163, 33- 43.

|

| 31 |

HU W F, CHEN W Y, WANG X B, et al. A computational framework for coating fatigue analysis of wind turbine blades due to rain erosion[J]. Renewable Energy, 2021, 170, 236- 250.

|

| 32 |

KAORE A N, KALE U B, YERRAMALLI C S, et al. Turbine specific fatigue life prediction model for wind turbine blade coatings subjected to rain erosion[J]. Materials Today Communications, 2022, 31, 103487.

|

| 33 |

PUGH K, NASH J W, REABURN G, et al. On analytical tools for assessing the raindrop erosion of wind turbine blades[J]. Renewable and Sustainable Energy Reviews, 2021, 137, 110611.

|

| 34 |

HERRING R, DYER K, MARTIN F, et al. The increasing importance of leading edge erosion and a review of existing protection solutions[J]. Renewable and Sustainable Energy Reviews, 2019, 115, 109382.

|

| 35 |

EISENBERG D, LAUSTSEN S, STEGE J. Wind turbine blade coating leading edge rain erosion model: development and validation[J]. Wind Energy, 2018, 21 (10): 942- 951.

|

| 36 |

WANG Y, ZHUPANSKA O I. Lightning strike thermal damage model for glass fiber reinforced polymer matrix composites and its application to wind turbine blades[J]. Composite Structures, 2015, 132, 1182- 1191.

|

| 37 |

CANDELA GAROLERA A, MADSEN S F, NISSIM M, et al. Lightning damage to wind turbine blades from wind farms in the U.S.[J]. IEEE Transactions on Power Delivery, 2014, 31 (3): 1043- 1049.

|

| 38 |

ALSABAGH A S Y, TIU W, XU Y G, et al. A review of the effects of ice accretion on the structural behavior of wind turbines[J]. Wind Engineering, 2013, 37 (1): 59- 70.

|

| 39 |

IBRAHIM G M, POPE K, MUZYCHKA Y S. Effects of blade design on ice accretion for horizontal axis wind turbines[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2018, 173, 39- 52.

|

| 40 |

Work Package 1: Icing[EB/OL]. (2019-07-23)[2022-11-15]. http://www.icewind.dtu.dk/section/wp_1.

|

| 41 |

刘文斌, 李时华. 某风电场机组叶片断裂原因分析[J]. 风能, 2019, (1): 88- 92.

|

|

LIU Wenbin, LI Shihua. Cause analysis of blade fracture of a wind farm unit[J]. Wind Energy, 2019, (1): 88- 92.

|

| 42 |

SIERRA-PÉREZ J, TORRES-ARREDONDO M A, GÜEMES A. Damage and nonlinearities detection in wind turbine blades based on strain field pattern recognition. FBGs, OBR and strain gauges comparison[J]. Composite Structures, 2016, 135, 156- 166.

|

| 43 |

YE X W, SU Y H, HAN J P. Structural health monitoring of civil infrastructure using optical fiber sensing technology: a comprehensive review[J]. The Scientific World Journal, 2014, 2014: 652329.

|

| 44 |

BOSE A K, ZHANG X Z, MADDIPATLA D, et al. Screen-printed strain gauge for micro-strain detection applications[J]. IEEE Sensors Journal, 2020, 20 (21): 12652- 12660.

|

| 45 |

深圳市勤联科技有限公司. 应变片, 共和应变片, 日本kyowa应变片, 昭和应变片, showa应变片, 应变片的原理, 种类, 结构, 应变片知识 [EB/OL]. (2021-10-10)[2022-11-15]. http://www.santektech.com/jjfa1/newsId=58.html.

|

| 46 |

LIU Z, LI Y J, ZHANG N, et al. Reliability analysis of CFRP-packaged FBG sensors using FMEA and FTA techniques[J]. Applied Sciences, 2021, 11 (22): 10859.

|

| 47 |

HSU T Y, SHIAO S Y, LIAO W I. Damage detection of rotating wind turbine blades using local flexibility method and long-gauge fiber Bragg grating sensors[J]. Measurement Science and Technology, 2018, 29 (1): 015108.

|

| 48 |

徐小强, 杜阳, 冒燕, 等. 光纤布拉格光栅柔性传感器研究进展[J]. 应用光学, 2021, 42 (5): 932- 940.

|

|

XU Xiaoqiang, DU Yang, MAO Yan, et al. Research progress of flexible sensor of fiber Bragg grating[J]. Journal of Applied Optics, 2021, 42 (5): 932- 940.

|

| 49 |

张照辉. 基于光纤传感技术的风力发电机结构状态评估方法[D]. 哈尔滨: 哈尔滨工业大学, 2020.

|

|

ZHANG Zhaohui. Structural state evaluation method of wind turbine based on optical fiber sensing technology[D]. Harbin: Harbin Institute of Technology, 2020.

|

| 50 |

LIU Z, LIU X, ZHU S P, et al. Reliability assessment of measurement accuracy for FBG sensors used in structural tests of the wind turbine blades based on strain transfer laws[J]. Engineering Failure Analysis, 2020, 112, 104506.

|

| 51 |

WEN B R, TIAN X L, JIANG Z H, et al. Monitoring blade loads for a floating wind turbine in wave basin model tests using Fiber Bragg Grating sensors: a feasibility study[J]. Marine Structures, 2020, 71, 102729.

|

| 52 |

DOLIŃSKI L, KRAWCZUK M. Damage detection in turbine wind blades by vibration based methods[J]. Journal of Physics: Conference Series, 2009, 181, 012086.

|

| 53 |

LOSS T, BERGMANN A. Vibration-based fingerprint algorithm for structural health monitoring of wind turbine blades[J]. Applied Sciences, 2021, 11 (9): 4294.

|

| 54 |

OCHIENG F X, HANCOCK C M, ROBERTS G W, et al. A review of ground-based radar as a noncontact sensor for structural health monitoring of in-field wind turbines blades[J]. Wind Energy, 2018, 21 (12): 1435- 1449.

|

| 55 |

DILEK A U, OGUZ A D, SATIS F, et al. Condition monitoring of wind turbine blades and tower via an automated laser scanning system[J]. Engineering Structures, 2019, 189, 25- 34.

|

| 56 |

HELMING P, VON FREYBERG A, SORG M, et al. Wind turbine tower deformation measurement using terrestrial laser scanning on a 3.4 MW wind turbine[J]. Energies, 2021, 14 (11): 3255.

|

| 57 |

MARKS R, GILLAM C, CLARKE A, et al. Damage detection in a composite wind turbine blade using 3D scanning laser vibrometry[J]. Proceedings of the Institution of Mechanical Engineers, Part C:Journal of Mechanical Engineering Science, 2017, 231 (16): 3024- 3041.

|

| 58 |

DI LORENZO E, PETRONE G, MANZATO S, et al. Damage detection in wind turbine blades by using operational modal analysis[J]. Structural Health Monitoring, 2016, 15 (3): 289- 301.

|

| 59 |

PACHECO-CHÉRREZ J, PROBST O. Vibration-based damage detection in a wind turbine blade through operational modal analysis under wind excitation[J]. Materials Today:Proceedings, 2022, 56, 291- 297.

|

| 60 |

TCHERNIAK D, MØLGAARD L L. Active vibration-based structural health monitoring system for wind turbine blade: demonstration on an operating Vestas V27 wind turbine[J]. Structural Health Monitoring:an International Journal, 2017, 16 (5): 536- 550.

|

| 61 |

顾永强, 冯锦飞, 张哲玮, 等. 基于模态参数的在役风力发电机叶片损伤识别研究[J]. 太阳能学报, 2022, 43 (3): 350- 355.

|

|

GU Yongqiang, FENG Jinfei, ZHANG Zhewei, et al. Research on blade damage identification of active wind turbine based on modal parameters[J]. Acta Energiae Solaris Sinica, 2022, 43 (3): 350- 355.

|

| 62 |

张则荣, 韩桐桐, 李影. 基于应变模态的风机叶片损伤诊断研究[J]. 可再生能源, 2021, 39 (3): 359- 364.

|

|

ZHANG Zerong, HAN Tongtong, LI Ying. Damage identification of wind turbine blade based on strain mode analysis[J]. Renewable Energy Resources, 2021, 39 (3): 359- 364.

|

| 63 |

WANG W J, XUE Y, HE C K, et al. Review of the typical damage and damage-detection methods of large wind turbine blades[J]. Energies, 2022, 15 (15): 5672.

|

| 64 |

GÓMEZ MUÑOZ C, GARCÍA MÁRQUEZ F. A new fault location approach for acoustic emission techniques in wind turbines[J]. Energies, 2016, 9 (1): 40.

|

| 65 |

HE Y Z, LI M C, MENG Z Q, et al. An overview of acoustic emission inspection and monitoring technology in the key components of renewable energy systems[J]. Mechanical Systems and Signal Processing, 2021, 148, 107146.

|

| 66 |

FU Z X, LUO Y, GU C H, et al. Reliability analysis of condition monitoring network of wind turbine blade based on wireless sensor networks[J]. IEEE Transactions on Sustainable Energy, 2019, 10 (2): 549- 557.

|

| 67 |

ZHAO Z M, CHEN N Z. Acoustic emission based damage source localization for structural digital twin of wind turbine blades[J]. Ocean Engineering, 2022, 265, 112552.

|

| 68 |

MOTAMED P K, ABEDIAN A, NASIRI M. Optimal sensors layout design based on reference-free damage localization with lamb wave propagation[J]. Structural Control and Health Monitoring, 2020, 27 (4): 32.

|

| 69 |

GIRIDHARA G, RATHOD V T, NAIK S, et al. Rapid localization of damage using a circular sensor array and Lamb wave based triangulation[J]. Mechanical Systems and Signal Processing, 2010, 24 (8): 2929- 2946.

|

| 70 |

贾辉, 张磊安, 王景华, 等. 基于声发射技术的风电叶片复合材料损伤模式识别[J]. 可再生能源, 2022, 40 (1): 67- 72.

|

|

JIA Hui, ZHANG Leian, WANG Jinghua, et al. Damage pattern recognition of wind turbine blade composite material based on acoustic emission technology[J]. Renewable Energy Resources, 2022, 40 (1): 67- 72.

|

| 71 |

张亚楠, 周勃, 俞方艾, 等. 含缺陷风电叶片复合材料的失稳状态识别和预测[J]. 太阳能学报, 2021, 42 (9): 318- 325.

|

|

ZHANG Yanan, ZHOU Bo, YU Fang'ai, et al. Identification and prediction of instability status of composites with defective wind power blades[J]. Acta Energiae Solaris Sinica, 2021, 42 (9): 318- 325.

|

| 72 |

PAN X, LIU Z D, XU R, et al. Early warning of damaged wind turbine blades using spatial-temporal spectral analysis of acoustic emission signals[J]. Journal of Sound and Vibration, 2022, 537, 117209.

|

| 73 |

XU D, LIU P F, CHEN Z P. Damage mode identification and singular signal detection of composite wind turbine blade using acoustic emission[J]. Composite Structures, 2021, 255, 112954.

|

| 74 |

声发射检测的基本原理[EB/OL]. (2020-05-22)[2022-11-15]. http://wpic.1006ss.com/e/action/ShowInfo.php?classid=9&id=8082.

|

| 75 |

BARLAS E, ZHU W J, SHEN W Z, et al. Consistent modelling of wind turbine noise propagation from source to receiver[J]. The Journal of the Acoustical Society of America, 2017, 142 (5): 3297- 3310.

|

| 76 |

SUN S L, WANG T Y, YANG H X, et al. Damage identification of wind turbine blades using an adaptive method for compressive beamforming based on the generalized minimax-concave penalty function[J]. Renewable Energy, 2022, 181, 59- 70.

|

| 77 |

KRAUSE T, OSTERMANN J. Damage detection for wind turbine rotor blades using airborne sound[J]. Structural Control and Health Monitoring, 2020, 27.

|

| 78 |

LIU W Y. A review on wind turbine noise mechanism and de-noising techniques[J]. Renewable Energy, 2017, 108, 311- 320.

|

| 79 |

CHANDRASEKHAR K, STEVANOVIC N, CROSS E J, et al. Damage detection in operational wind turbine blades using a new approach based on machine learning[J]. Renewable Energy, 2021, 168, 1249- 1264.

|

| 80 |

董小泊. 基于DBSCAN的风电叶片音频分类研究[J]. 科技创新与应用, 2022, 12 (4): 23- 25.

|

| 81 |

POOZESH P, AIZAWA K, NIEZRECKI C, et al. Structural health monitoring of wind turbine blades using acoustic microphone array[J]. Structural Health Monitoring, 2017, 16 (4): 471- 485.

|

| 82 |

TRAYLOR C, DIPAOLA M, WILLIS D J, et al. A computational investigation of airfoil aeroacoustics for structural health monitoring of wind turbine blades[J]. Wind Energy, 2020, 23 (3): 795- 809.

|

| 83 |

YANG W X, COURT R, JIANG J S. Wind turbine condition monitoring by the approach of SCADA data analysis[J]. Renewable Energy, 2013, 53, 365- 376.

|

| 84 |

JIN X H, XU Z W, QIAO W. Condition monitoring of wind turbine generators using SCADA data analysis[J]. IEEE Transactions on Sustainable Energy, 2021, 12 (1): 202- 210.

|

| 85 |

LIU X C, DU J, YE Z S. A condition monitoring and fault isolation system for wind turbine based on SCADA data[J]. IEEE Transactions on Industrial Informatics, 2022, 18 (2): 986- 995.

|

| 86 |

SCHLECHTINGEN M, SANTOS I F. Wind turbine condition monitoring based on SCADA data using normal behavior models. part 2: application examples[J]. Applied Soft Computing, 2014, 14, 447- 460.

|

| 87 |

BANGALORE P, LETZGUS S, KARLSSON D, et al. An artificial neural network-based condition monitoring method for wind turbines, with application to the monitoring of the gearbox[J]. Wind Energy, 2017, 20 (8): 1421- 1438.

|

| 88 |

KONG Z Q, TANG B P, DENG L, et al. Condition monitoring of wind turbines based on spatio-temporal fusion of SCADA data by convolutional neural networks and gated recurrent units[J]. Pergamon, 2020,15:146.

|

| 89 |

MCKINNON C, CARROLL J, MCDONALD A, et al. Investigation of isolation forest for wind turbine pitch system condition monitoring using SCADA data[J]. Energies, 2021, 14 (20): 6601.

|

| 90 |

PANDIT R K, INFIELD D. SCADA based wind turbine anomaly detection using Gaussian Process (GP) models for wind turbine condition monitoring purposes[J]. IET Renewable Power Generation, 2018, 12 (11): 1249- 1255.

|

| 91 |

董健, 柳亦兵, 滕伟, 等. 基于BP_Adaboost算法的风电机组叶片结冰检测[J]. 可再生能源, 2021, 39 (5): 632- 636.

|

|

DONG Jian, LIU Yibing, TENG Wei, et al. Wind turbine blade ice detection based on BP_Adaboost algorithm[J]. Renewable Energy Resources, 2021, 39 (5): 632- 636.

|

| 92 |

张鑫, 徐遵义, 何慧茹, 等. 基于RBM和SVM的风电机组叶片开裂故障预测[J]. 电力系统保护与控制, 2020, 48 (15): 134- 140.

|

|

ZHANG Xin, XU Zunyi, HE Huiru, et al. Wind turbine blade cracking fault prediction based on RBM and SVM[J]. Power System Protection and Control, 2020, 48 (15): 134- 140.

|

| 93 |

MATSUI T, YAMAMOTO K, OGATA J. Anomaly detection using a SCADA feature extractor and machine learning to detect lightning damage on wind turbine blades[J]. IEEJ Transactions on Electrical and Electronic Engineering, 2022, 17 (6): 945- 951.

|

| 94 |

LIU Y, CHENG H, KONG X G, et al. Intelligent wind turbine blade icing detection using supervisory control and data acquisition data and ensemble deep learning[J]. Energy Science & Engineering, 2019, 7 (6): 2633- 2645.

|

| 95 |

LI X L. Few-shot wind turbine blade damage early warning system based on sound signal fusion[J]. Multimedia Systems, 2022: 1–10.

|

| 96 |

DOWNEY A, UBERTINI F, LAFLAMME S. Algorithm for damage detection in wind turbine blades using a hybrid dense sensor network with feature level data fusion[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2017, 168, 288- 296.

|

| 97 |

ZHANG T, XU F Y, JIA M P. A centrifugal fan blade damage identification method based on the multi-level fusion of vibro-acoustic signals and CNN[J]. Measurement, 2022, 199, 111475.

|

| 98 |

SANATI H, WOOD D, SUN Q A. Condition monitoring of wind turbine blades using active and passive thermography[J]. Applied Sciences, 2018, 8 (10): 2004.

|

| 99 |

MARQUES R, UNEL M, YILDIZ M, et al. Remaining useful life prediction of laminated composite materials using thermoelastic stress analysis[J]. Composite Structures, 2019, 210, 381- 390.

|

| 100 |

JENSEN F, TERLAU M, SORG M, et al. Active thermography for the detection of sub-surface defects on a curved and coated GFRP-structure[J]. Applied Sciences, 2021, 11 (20): 9545.

|

| 101 |

DOROSHTNASIR M, WORZEWSKI T, KRANKENHAGEN R, et al. On-site inspection of potential defects in wind turbine rotor blades with thermography[J]. Wind Energy, 2016, 19 (8): 1407- 1422.

|

| 102 |

康爽, 陈长征, 周勃, 等. 基于温度阈值风电叶片缺陷识别的红外检测研究[J]. 太阳能学报, 2020, 41 (8): 337- 341.

|

|

KANG Shuang, CHEN Changzheng, ZHOU Bo, et al. Infrared detection research on wind turbine blade defects identification based on temperature threshold[J]. Acta Energiae Solaris Sinica, 2020, 41 (8): 337- 341.

|

| 103 |

HWANG S, AN Y K, YANG J, et al. Remote inspection of internal delamination in wind turbine blades using continuous line laser scanning thermography[J]. International Journal of Precision Engineering and Manufacturing-Green Technology, 2020, 7 (3): 699- 712.

|

| 104 |

GALLEGUILLOS C, ZORRILLA A, JIMENEZ A, et al. Thermographic non-destructive inspection of wind turbine blades using unmanned aerial systems[J]. Plastics, Rubber and Composites, 2015, 44 (3): 98- 103.

|

| 105 |

使用高像素红外摄像机的无损检测方法介绍[EB/OL]. (2020-07-15)[2022-11-15]. https://www.elecfans.com/article/85/2020/202007151246376.html.

|

| 106 |

红外热像仪在风力发电机叶片检修的应用[EB/OL]. (2019-08-28)[2022-11-15]. https://www.chem17.com/tech_news/detail/1948210.html.

|

| 107 |

XU D H, WEN C B, LIU J H. Wind turbine blade surface inspection based on deep learning and UAV-taken images[J]. Journal of Renewable and Sustainable Energy, 2019, 11 (5): 1- 8.

|

| 108 |

WANG L, ZHANG Z J. Automatic detection of wind turbine blade surface cracks based on UAV-taken images[J]. IEEE Transactions on Industrial Electronics, 2017, 64 (9): 7293- 7303.

|

| 109 |

YANG X Y, ZHANG Y F, LV W, et al. Image recognition of wind turbine blade damage based on a deep learning model with transfer learning and an ensemble learning classifier[J]. Renewable Energy, 2021, 163, 386- 397.

|

| 110 |

BARKER J W, BHOWMIK N, BRECKON T P. Semi-supervised surface anomaly detection of composite wind turbine blades from drone imagery[EB/OL]. (2021-12-01)[2022-11-15].https://arxiv.org/abs/2112.00556.

|

| 111 |

DENG L W, GUO Y G, CHAI B R. Defect detection on a wind turbine blade based on digital image processing[J]. Processes, 2021, 9 (8): 1452.

|

| 112 |

PENG L, LIU J. Detection and analysis of large-scale WT blade surface cracks based on UAV-taken images[J]. IET Image Processing, 2018, 12 (11): 2059- 2064.

|

| 113 |

无人机为风电巡检做了什么呢?-搜狐[EB/OL]. (2017-01-10)[2022-12-27]. http://mt.sohu.com/20170110/n478281899.

|