| 1 |

IEA. CO2 emissions in 2023[R/OL]. (2024-03-01) [2024-11-27]. https://www.iea.org/reports/co2-emissions-in-2023#overview.

|

| 2 |

习近平. 在第七十五届联合国大会一般性辩论上的讲话[N]. 中华人民共和国国务院公报, 2020(28): 5–7.

|

| 3 |

舒印彪, 张丽英, 张运洲, 等. 我国电力碳达峰、碳中和路径研究[J]. 中国工程科学, 2021, 23 (6): 1- 14.

|

|

SHU Yinbiao, ZHANG Liying, ZHANG Yunzhou, et al. Carbon peak and carbon neutrality path for China's power industry[J]. Strategic Study of CAE, 2021, 23 (6): 1- 14.

|

| 4 |

陈胜, 卫志农, 顾伟, 等. 碳中和目标下的能源系统转型与变革: 多能流协同技术[J]. 电力自动化设备, 2021, 41 (9): 3- 12.

|

|

CHEN Sheng, WEI Zhinong, GU Wei, et al. Carbon neutral oriented transition and revolution of energy systems: multi-energy flow coordination technology[J]. Electric Power Automation Equipment, 2021, 41 (9): 3- 12.

|

| 5 |

XU J, GUAN Y, OLDFIELD J, et al. China carbon emission accounts 2020-2021[J]. Applied Energy, 2024, 360, 122837.

|

| 6 |

郑国光. 支撑“双碳”目标实现的问题辨识与关键举措研究[J]. 中国电力, 2023, 56 (11): 1- 8.

|

|

ZHENG Guoguang. Problem identification and key measures to support the achievement of carbon peak and carbon neutrality[J]. Electric Power, 2023, 56 (11): 1- 8.

|

| 7 |

周原冰, 张士宁, 侯方心, 等. 电力行业碳达峰及促进全社会碳减排影响分析[J]. 中国电力, 2024, 57 (9): 1- 9.

|

|

ZHOU Yuanbing , ZHANG Shining, HOU Fangxin , et al. Analysis of carbon peaking in power sector and its impact on promoting whole-society carbon emissions reduction[J]. Electric Power, 2024, 57 (9): 1- 9.

|

| 8 |

陈晓红, 付益鹏, 黄骋东, 等. 特高压工程建设碳排放测算方法与应用[J]. 资源科学, 2023, 45 (12): 2291- 2310.

|

|

CHEN Xiaohong, FU Yipeng, HUANG Chengdong, et al. Method and application of carbon emission calculation for ultra- high voltage (UHV) project construction[J]. Resources Science, 2023, 45 (12): 2291- 2310.

|

| 9 |

WEI W, LI J, CHEN B, et al. Embodied greenhouse gas emissions from building China's large-scale power transmission infrastructure[J]. Nature Sustainability, 2021, 4 (8): 739- 747.

|

| 10 |

LI F, YE Z, XIAO X, et al. Material stocks and flows of power infrastructure development in China[J]. Resources, Conservation and Recycling, 2020, 160, 104906.

|

| 11 |

国家电网. 国家电网公司“碳达峰、碳中和”行动方案[J]. 国家电网, 2021, (3): 50–52.

|

| 12 |

李小冬, 朱辰. 我国建筑碳排放核算及影响因素研究综述[J]. 安全与环境学报, 2020, 20 (1): 317- 327.

|

|

LI Xiaodong, ZHU Chen. Summary of research on account of carbon emission in building industry and analysis of its influential factors[J]. Journal of Safety and Environment, 2020, 20 (1): 317- 327.

|

| 13 |

闫云凤, 赵忠秀. 中国对外贸易隐含碳的测度研究—基于碳排放责任界定的视角[J]. 国际贸易问题, 2012, (1): 131- 142.

|

|

YAN Yunfeng, ZHAO Zhongxiu. CO2 emissions embodied in China's international trade: a perspective of allocating international responsibilities[J]. Journal of International Trade, 2012, (1): 131- 142.

|

| 14 |

刘明达, 蒙吉军, 刘碧寒. 国内外碳排放核算方法研究进展[J]. 热带地理, 2014, 34 (2): 248- 258.

|

|

LIU Mingda, MENG Jijun, LIU Bihan. Progress in the studies of carbon emission estimation[J]. Tropical Geography, 2014, 34 (2): 248- 258.

|

| 15 |

张喜泽. 上海公里级高温超导电缆输电工程碳排放分析[J]. 低温与超导, 2022, 50 (12): 21- 24, 39.

|

|

ZHANG Xize. Carbon emission analysis of Shanghai kilometer-scale HTS cable transmission project[J]. Cryogenics & Superconductivity, 2022, 50 (12): 21- 24, 39.

|

| 16 |

TURCONI R, SIMONSEN C G, BYRIEL I P, et al. Life cycle assessment of the Danish electricity distribution network[J]. The International Journal of Life Cycle Assessment, 2014, 19, 100- 108.

|

| 17 |

JORGE R S, HERTWICH E G. Environmental evaluation of power transmission in Norway[J]. Applied energy, 2013, 101, 513- 520.

|

| 18 |

游一民, 彭振搏, 戴冬云, 等. 40.5 kV C-GIS全生命周期内碳排放计算与分析[J]. 高压电器, 2022, 58 (9): 13- 19.

|

|

YOU Yimin, PENG Zhenbo, DAI Dongyun, et al. Calculation and analysis of carbon emission in the whole life cycle of 40.5 kV C-GIS[J]. High Voltage Apparatus, 2022, 58 (9): 13- 19.

|

| 19 |

王珊珊, 张寒, 杨红强. 中国人造板行业的生命周期碳足迹和能源耗用评估[J]. 资源科学, 2019, 41 (3): 521- 531.

|

|

WANG Shanshan, ZHANG Han, YANG Hongqiang. Carbon footprint and energy consumption based on life cycle assessment of wood-based panel industry in China[J]. Resources Science, 2019, 41 (3): 521- 531.

|

| 20 |

IPCC. 2006 IPCC guidance for national greenhouse gas inventories[R]. Japan: IGES, 2006.

|

| 21 |

国家标准化管理委员会. 工业企业温室气体排放核算和报告通则: GB/T 32150—2015[S]. 北京: 中国标准出版社, 2015.

|

| 22 |

WEI W, WANG M, ZHANG P, et al. A 2015 inventory of embodied carbon emissions for Chinese power transmission infrastructure projects[J]. Scientific data, 2020, 7 (1): 318.

|

| 23 |

WEI W, WU X, LI J, et al. Ultra-high voltage network induced energy cost and carbon emissions[J]. Journal of Cleaner Production, 2018, 178, 276- 292.

|

| 24 |

JORGE R S, HAWKINS T R, HERTWICH E G. Life cycle assessment of electricity transmission and distribution—part 1: power lines and cables[J]. The International Journal of Life Cycle Assessment, 2012, 17, 9- 15.

|

| 25 |

BLACKETT G, SAVORY E, TOY N, et al. An evaluation of the environmental burdens of present and alternative materials used for electricity transmission[J]. Building and environment, 2008, 43 (7): 1326- 1338.

|

| 26 |

BUMBY S, DRUZHININA E, FERALDI R, et al. Life cycle assessment of overhead and underground primary power distribution[J]. Environmental science & technology, 2010, 44 (14): 5587- 5593.

|

| 27 |

HARRISON G P, KARAMANLIS S, OCHOA L F. Life cycle assessment of the transmission network in Great Britain[J]. Energy policy, 2010, 38 (7): 3622- 3631.

|

| 28 |

JORGE R S, HAWKINS T R, HERTWICH E G. Life cycle assessment of electricity transmission and distribution—part 2: transformers and substation equipment[J]. The International Journal of Life Cycle Assessment, 2012, 17, 184- 191.

|

| 29 |

省级温室气体清单编制指南编写组. 省级温室气体清单编制指南[R]. 北京: 国家发展和改革委员会, 2011.

|

| 30 |

郭春, 郭亚林, 陈政. 交通隧道工程碳排放核算及研究进展分析[J]. 现代隧道技术, 2023, 60 (1): 1- 10.

|

|

GUO Chun, GUO Yalin, CHEN Zheng. Carbon emission accounting and research progress analysis of traffic tunnel engineering[J]. Modern Tunnelling Technology, 2023, 60 (1): 1- 10.

|

| 31 |

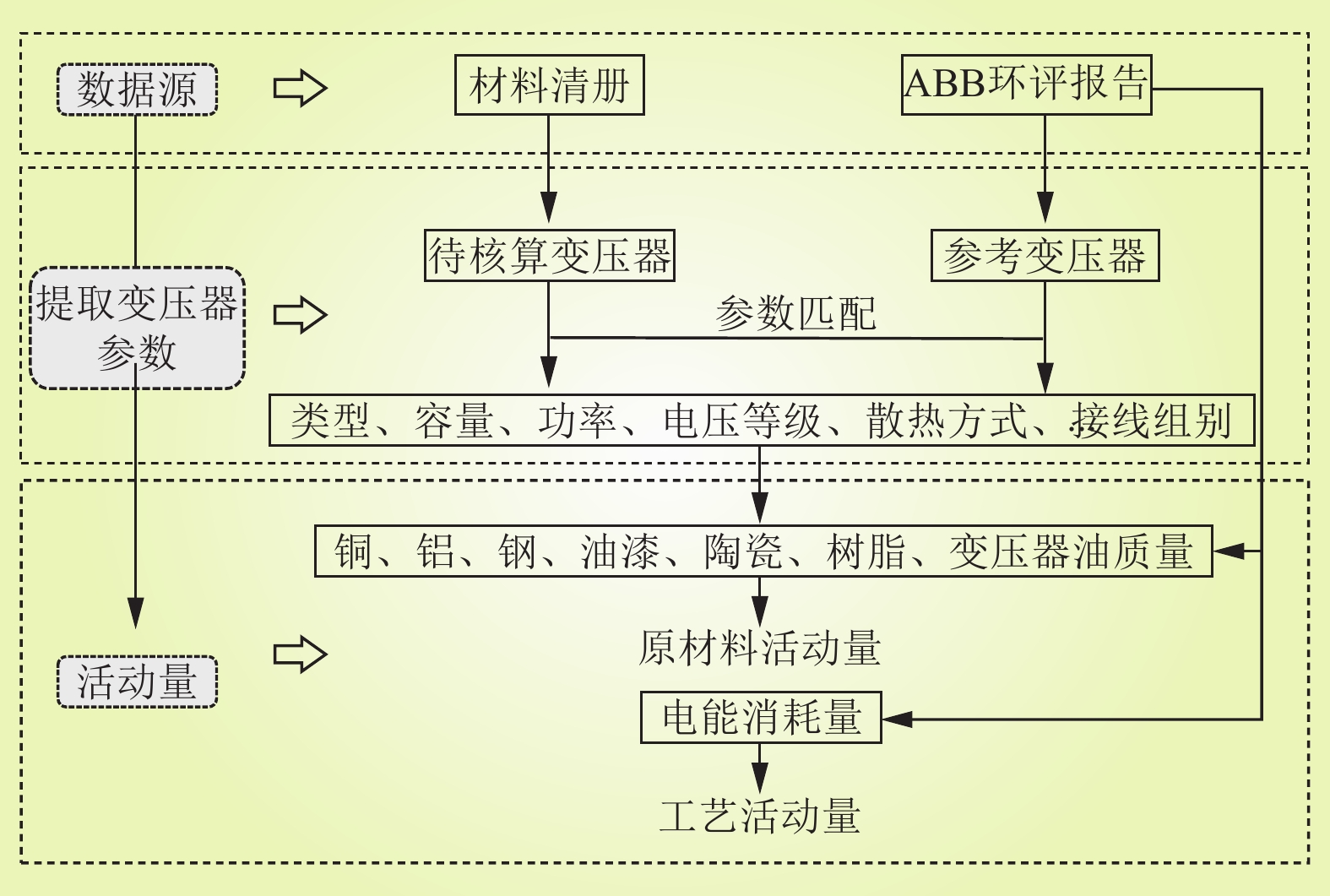

ABB. Environmental product declaration[R/OL]. (2003-11-25) [2023-08-14]. https://library.abb.com.

|

| 32 |

李侠, SACHS G, UDER M. ±800 kV特高压直流输电用6英寸大功率晶闸管换流阀[J]. 高压电器, 2010, 46 (6): 1- 5.

|

|

LI Xia, SACHS G, UDER M. 6 inch high power thyristor valves for ±800 kV UHVDC transmission[J]. High Voltage Apparatus, 2010, 46 (6): 1- 5.

|

| 33 |

中国城市温室气体工作组(CCG). 中国产品全生命周期温室气体排放系数库[EB/OL], 2022. http://lca.cityghg.com/.

|

| 34 |

西安西电电力系统有限公司. 换流阀产品碳足迹报告[R/OL]. (2021-03-15) [2024-12-15]. http://www.xdps.com.cn/info/1085/2342.htm.

|

| 35 |

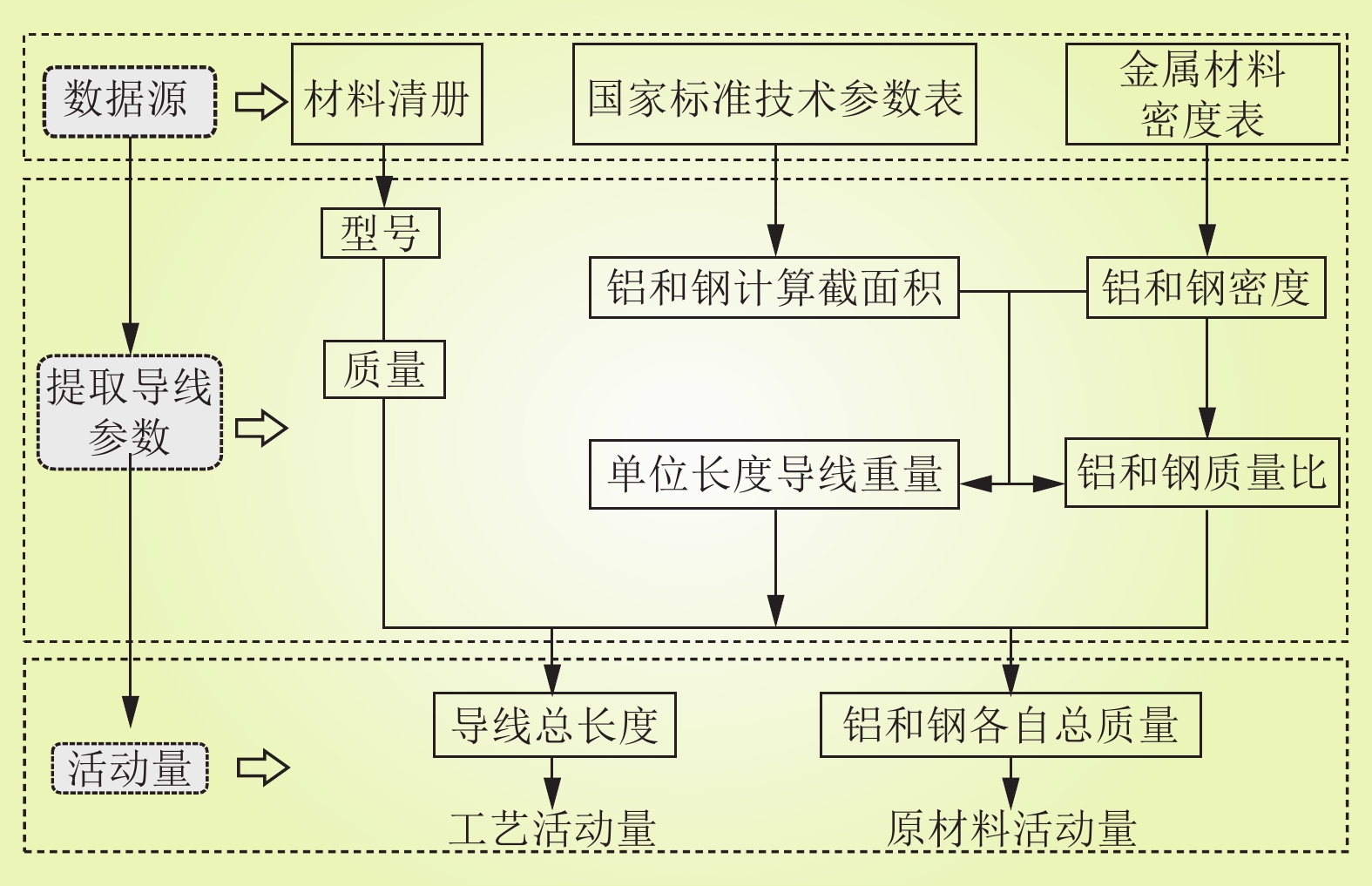

国家标准化管理委员会. 圆线同心绞架空导线: GB/T 1179—2017 [S]. 北京: 中国标准出版社, 2017.

|

| 36 |

国家标准化管理委员会. ±800kV直流输电线路金具技术规范: GB/T 31235—2014 [S]. 北京: 中国标准出版社, 2014.

|

| 37 |

彭卓, 郭春梅, 汪磊磊, 等. 绿色建筑全生命周期CO2排放敏感性与减碳潜力研究[J]. 天津城建大学学报, 2021, 27 (6): 436- 441.

|

|

PENG Zhuo, GUO Chunmei, WANG Leilei, et al. Total life-cycle analysis of CO2 emission sensitivity and reduction potential of green building[J]. Journal of Tianjin Chengjian University, 2021, 27 (6): 436- 441.

|