| 1 |

张志勇, 莫华, 王猛, 等. 600MW燃煤机组烟气污染物控制研究[J]. 中国电力, 2022, 55 (5): 204- 210.

|

|

ZHANG Zhiyong, MO Hua, WANG Meng, et al. Study of flue gas pollutant control in a 600 MW coal-fired unit[J]. Electric Power, 2022, 55 (5): 204- 210.

|

| 2 |

禾志强, 周鹏, 张铭, 等. 有机酸添加剂在石灰石–石膏法脱硫中应用的试验研究[J]. 中国电机工程学报, 2011, 31 (23): 34- 40.

DOI

|

|

HE Zhiqiang, ZHOU Peng, ZHANG Ming, et al. Experimental study of the application of organic acids on lmiestone-gypsum desulfurization[J]. Proceedings of the CSEE, 2011, 31 (23): 34- 40.

DOI

|

| 3 |

LIM J H, CHO H T, LIM J. Optimization of wet flue gas desulfurization system using recycled waste oyster shell as high-grade limestone substitutes[J]. Journal of Cleaner Production, 2021, 318, 1- 15.

|

| 4 |

曲江源, 齐娜娜, 关彦军, 等. 湿法烟气脱硫塔内传递与化学反应过程CFD模拟[J]. 化工学报, 2019, 70 (6): 2117- 2128.

DOI

|

|

QU Jiangyuan, QI Nana, GUAN Yanjun, et al. CFD simulation of transfer and chemical reaction process in wet flue gas desulfurization tower[J]. CIESC Journal, 2019, 70 (6): 2117- 2128.

DOI

|

| 5 |

侯建勇, 严芳, 王浩, 等. 基于因果-模糊层次分析的湿法脱硫系统运行稳定性综合评价[J]. 化工进展, 2022, 41 (2): 569- 583.

|

|

HOU Jianyong, YAN Fang, WANG Hao, et al. Comprehensive evaluation of operation stability of wet desulfurization system based on causal-fuzzy AHP[J]. Chemical Industry and Engineering Progress, 2022, 41 (2): 569- 583.

|

| 6 |

曹国庆, 邢金城, 涂光备. 基于灰色层次分析理论的烟气脱硫技术评价方法[J]. 中国电机工程学报, 2006, 26 (4): 51- 55.

DOI

|

|

CAO Guoqing, XING Jincheng, TU Guangbei. Grey method with use of an analytic hierarchy process for performance evaluation of flue gas desulfurization technology[J]. Proceedings of the CSEE, 2006, 26 (4): 51- 55.

DOI

|

| 7 |

马双忱, 周权, 曹建宗, 等. 湿法脱硫系统动态过程建模与仿真[J]. 化工学报, 2020, 71 (8): 3741- 3751.

|

|

MA Shuangchen, ZHOU Quan, CAO Jianzong, et al. Modeling and simulation of wet desulfurization system dynamic process[J]. CIESC Jorunal, 2020, 71 (8): 3741- 3751.

|

| 8 |

吴磊, 康英伟. 基于改进粒子群优化长短时记忆神经网络的脱硫系统SO2预测模型 [J]. 热力发电, 2021, 50 (12): 66- 73.

|

|

WU Lei, KANG Yingwei. Prediction model of SO2 concentration in desulfurization system based on improved particle swarm optimization LSTM [J]. Thermal Power Generation, 2021, 50 (12): 66- 73.

|

| 9 |

许丹, 沈凯, 张亚平, 等. 基于模糊理论的湿法脱硫故障诊断和优化模型研究[J]. 环境工程, 2018, 36 (2): 92- 97.

DOI

|

|

XU Dan, SHEN Kai, ZHANG Yaping, et al. Study on fault diagnosis and operation optimization models of WFGD based on fuzzy theory[J]. Environmental Engineering, 2018, 36 (2): 92- 97.

DOI

|

| 10 |

张锦航, 乔宗良, 司风琪. 基于模糊理论的脱硫系统故障诊断[J]. 工业控制计算机, 2021, 34 (9): 92- 96.

DOI

|

|

ZHANG Jinhang, QIAO Zongliang, SI Fengqi. Fault diagnosis of desulfurization system based on fuzzy theory[J]. Industrial Control Computer, 2021, 34 (9): 92- 96.

DOI

|

| 11 |

徐遵义, 刘文慧, 张旭冉, 等. 基于数据驱动的浆液循环泵运行优化研究[J]. 中国电力, 2021, 54 (3): 197- 204.

|

|

XU Zunyi, LIU Wenhui, ZHANG Xuran, et al. Research on data-driven optimal operation of slurry circulation pump[J]. Electric Power, 2021, 54 (3): 197- 204.

|

| 12 |

范昊鹏, 夏凤毅, 包军宇, 等. 基于PFC预测的燃煤机组脱硫优化控制[J]. 动力工程学报, 2020, 40 (10): 808- 814.

DOI

|

|

FAN Haopeng, XIA Fengyi, BAO Junyu, et al. Optimized control for desulphurization of coal-fired units based on PFC prediction[J]. Journal of Chinese Society of Power Engineering, 2020, 40 (10): 808- 814.

DOI

|

| 13 |

GU H, CUI Y F, ZHU H X, et al. A new approach for clustering in desulfurization system based on modified framework for gypsum slurry quality monitoring[J]. Energy, 2018, 148, 789- 801.

DOI

|

| 14 |

贾西部, 金万元, 李兴华, 等. 石灰石-石膏湿法烟气脱硫系统浆液起泡原因分析[J]. 中国电力, 2015, 48 (9): 157- 160.

|

|

JIA Xibu, JIN Wanyuan, LI Xinghua, et al. Cause analysis on slurry foaming in wet limestone-gypsum flue gas desulfurization system[J]. Electric Power, 2015, 48 (9): 157- 160.

|

| 15 |

董锐锋, 陈浩军, 王锋涛, 等. 单塔双循环脱硫系统结垢问题研究[J]. 中国电力, 2018, 51 (4): 149- 154.

|

|

DONG Ruifeng, CHEN Haojun, WANG Fengtao, et al. Research on scale problem of single tower with dual loop desulfurization system[J]. Electric Power, 2018, 51 (4): 149- 154.

|

| 16 |

薛建明, 王小明, 刘建民, 等. 湿法烟气脱硫设计及设备选型手册[M]. 北京: 中国电力出版社, 2011: 133–139.

|

| 17 |

石少晴, 余琬冰, 蒋惠梦, 等. 湿法脱硫系统中二水硫酸钙结晶特性分析[J]. 环境工程, 2019, 37 (3): 104- 108.

DOI

|

|

SHI Shaoqing, YU Wanbing, JIANG Huimeng, et al. Study on crystalline properties of calcium sulfate dihydrate in wet desulfurization system[J]. Environmental Engineering, 2019, 37 (3): 104- 108.

DOI

|

| 18 |

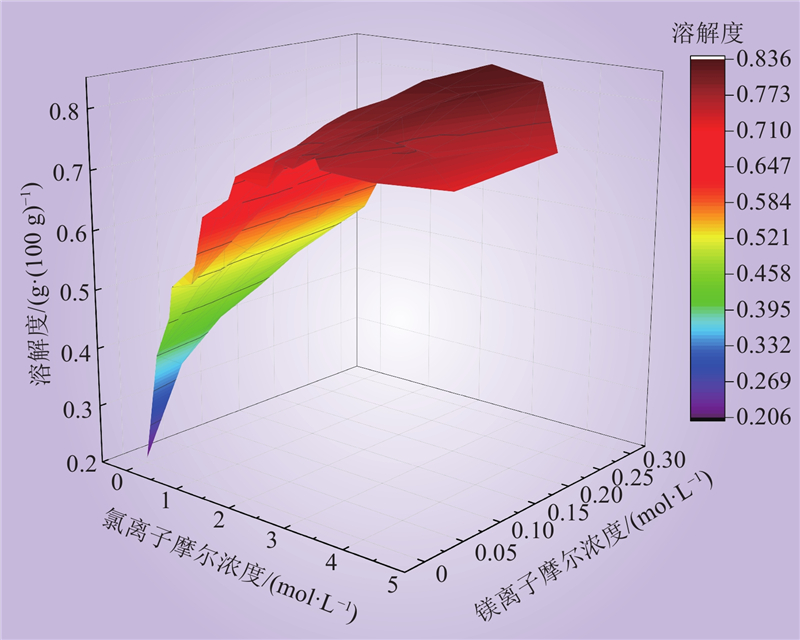

赖富国, 高国华, 肖燕飞, 等. 氯-硫酸盐体系下硫酸钙溶解度相图的研究进展[J]. 无机盐工业, 2018, 50 (8): 16- 21.

|

|

LAI Fuguo, GAO Guohua, XIAO Yanfei, et al. Research progress on solubility phase diagrams of calcium sulfate in chloride-sulfate solutions[J]. Inorganic Chemicals Industry, 2018, 50 (8): 16- 21.

|

| 19 |

YU B J, MIAO S S, ZHANG Y J, et al. Determination and analysis of the solubility of CaSO4·2H2O and αCaSO4·0.5H2O in formamide aqueous solutions at T = 303.15–363.15 K [J]. Journal of Chemical & Engineering Data, 2020, 65 (9): 4395- 4405.

|

| 20 |

张飞宇. 湿法烟气脱硫石膏成核与结晶特性研究[D]. 北京: 华北电力大学, 2021.

|

|

ZHANG Feiyu. Study on nucleation and crystallization characteristics of wet flue gas desulfurization gypsum[D]. Beijing: North China Electric Power University, 2021.

|

| 21 |

OSTROFF A G, METLER A V. Solubility of calcium sulfate dihydrate in the system NaCl-MgCl2-H2O from 28 ℃ to 70 ℃ [J]. Journal of Chemical & Engineering Data, 1966, 11 (3): 346- 350.

|

| 22 |

岳春妹, 陶雷行, 陈洪涛, 等. 脱硫浆液硫酸钙过饱和度的研究[J]. 华东电力, 2012, 40 (6): 1082- 1084.

|

|

YUE Chunmei, TAO Leixing, CHEN Hongtao, et al. Supersaturation of calcium sulfate dihydrate in desulfurization slurry[J]. East China Electric Power, 2012, 40 (6): 1082- 1084.

|

| 23 |

崔仕文, 铁治欣, 丁成富, 等. 基于偏最小二乘支持向量机的烟气湿法脱硫效率预测模型[J]. 热力发电, 2017, 46 (4): 81- 87.

DOI

|

|

CUI Shiwen, TIE Zhixin, DING Chengfu, et al. Prediction model for flue gas wet desulfurization efficiency based on partial least squares support vector machine[J]. Thermal Power Generation, 2017, 46 (4): 81- 87.

DOI

|

| 24 |

齐年哲. 石灰石-石膏湿法烟气脱硫效率的软测量技术[D]. 北京: 华北电力大学, 2013.

|

|

QI Nianzhe. Soft sensing technology of limestone-gypsum wet flue gas desulfurization efficiency[D]. Beijing: North China Electric Power University, 2013.

|

| 25 |

ZHAO Z Y, ZHANG Y X, GAO W C, et al. Simulation of SO2 absorption and performance enhancement of wet flue gas desulfurization system [J]. Process Safety and Environmental Protection, 2021, 150, 453- 463.

DOI

|

| 26 |

JIANG L, QIU Y L, LI Y. Effect analysis of quantum chemical descriptors and substituent characteristics on Henry's law constants of polybrominated diphenyl ethers at different temperatures[J]. Ecotoxicology and Environmental Safety, 2017, 145, 176- 183.

DOI

|

| 27 |

宋炎. 脱硫浆液组成变化对起泡影响机理研究[D]. 淮南: 安徽理工大学, 2018.

|

|

SONG Yan. Study on the influence mechanism of desulfurization slurry composition change on foaming[D]. Huainan: Anhui University of Science & Technology, 2018.

|

| 28 |

JIANG L, LI Y. Modification of PBDEs (BDE-15, BDE-47, BDE-85 and BDE-126) biological toxicity, bio-concentration, persistence and atmospheric long-range transport potential based on the pharmacophore modeling assistant with the full factor experimental design[J]. Journal of Hazardous Materials, 2016, 307, 202- 212.

DOI

|