| 1 |

郑林烽, 缪源诚, 滕晓毕, 等. 考虑配储的火电机组灵活性改造模型与方法[J]. 中国电机工程学报, 2025, 45 (4): 1501- 1513.

|

|

ZHENG Linfeng, MIAO Yuancheng, TENG Xiaobi, et al. Model and method for flexible retrofit of thermal power units considering energy storage configuration[J]. Proceedings of the CSEE, 2025, 45 (4): 1501- 1513.

|

| 2 |

国务院. 2030年前碳达峰行动方案的通知[EB/OL]. (2021-10-26)[2024-02-26]. https://www.gov.cn/zhengce/content/2021-10/26/content_5644984.htm.

|

| 3 |

章建华. 深入学习贯彻习近平总书记重要讲话精神 以更大力度推动我国新能源高质量发展[N]. 时事报告, 2024-05-10.

|

| 4 |

麻秀范, 王戈, 朱思嘉, 等. 计及风电消纳与发电集团利益的日前协调优化调度[J]. 电工技术学报, 2021, 36 (3): 579- 587.

|

|

MA Xiufan, WANG Ge, ZHU Sijia, et al. Coordinated day-ahead optimal dispatch considering wind power consumption and the benefits of power generation group[J]. Transactions of China Electrotechnical Society, 2021, 36 (3): 579- 587.

|

| 5 |

戴斌, 陈广伟, 孙海峰, 等. 煤电机组灵活性改造的政策导向及趋势[J]. 电力学报, 2023, 38 (3): 247- 253.

|

|

DAI Bin, CHEN Guangwei, SUN Haifeng, et al. Policy arientation and trend of flexible transformation of coal-fired power units[J]. Journal of Electric Power, 2023, 38 (3): 247- 253.

|

| 6 |

戈志华, 曾质彬, 卫慧敏, 等. 供热机组低压缸近零出力低压流场和温度场数值模拟与分析[J]. 中国电机工程学报, 2023, 43 (19): 7549- 7559.

|

|

GE Zhihua, ZENG Zhibin, WEI Huimin, et al. Numerical simulation and analysis of low pressure flow field and temperature field distribution near zero output in low pressure cylinder of heat-supply unit[J]. Proceedings of the CSEE, 2023, 43 (19): 7549- 7559.

|

| 7 |

黄畅, 张攀, 王卫良, 等. 燃煤发电产业升级支撑我国节能减排与碳中和国家战略[J]. 热力发电, 2021, 50 (4): 1- 6.

|

|

HUANG Chang, ZHANG Pan, WANG Weiliang, et al. The upgradation of coal-fired power generation industry supports China’s energy conservation, emission reduction and carbon neutrality[J]. Thermal Power Generation, 2021, 50 (4): 1- 6.

|

| 8 |

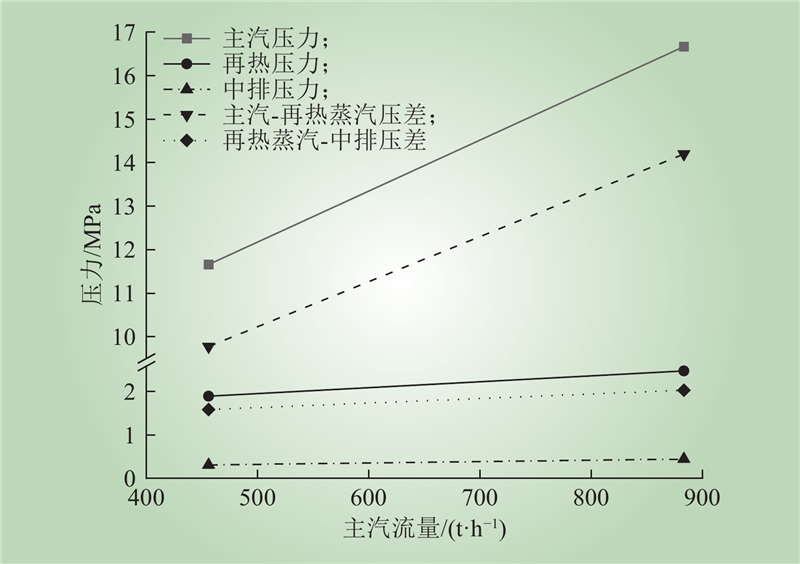

郝建成, 王凯润, 李庆华, 等. 350MW超临界机组热电调峰特性分析[J]. 汽轮机技术, 2023, 65 (6): 465- 468, 443.

|

|

HAO Jiancheng, WANG Kairun, LI Qinghua, et al. Analysis of the thermal-electrolytic coupling characteristics of a 350MW supercritical unit[J]. Turbine Technology, 2023, 65 (6): 465- 468, 443.

|

| 9 |

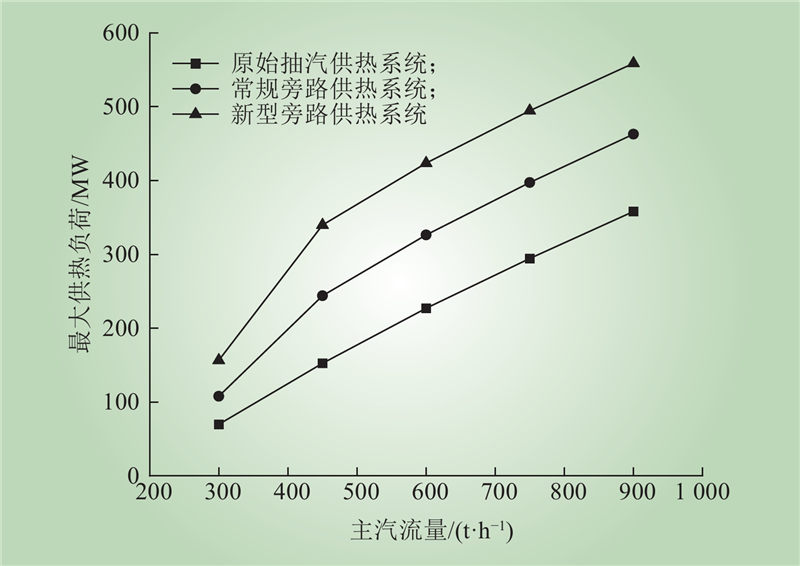

高耀岿, 曾德良, 平博宇, 等. 含两级旁路供热机组安全区计算[J]. 华北电力大学学报(自然科学版), 2020, 47 (5): 86- 92.

|

|

GAO Yaokui, ZENG Deliang, PING Boyu, et al. Calculation of safe operation area for CHP units with two-stage bypass[J]. Journal of North China Electric Power University (Natural Science Edition), 2020, 47 (5): 86- 92.

|

| 10 |

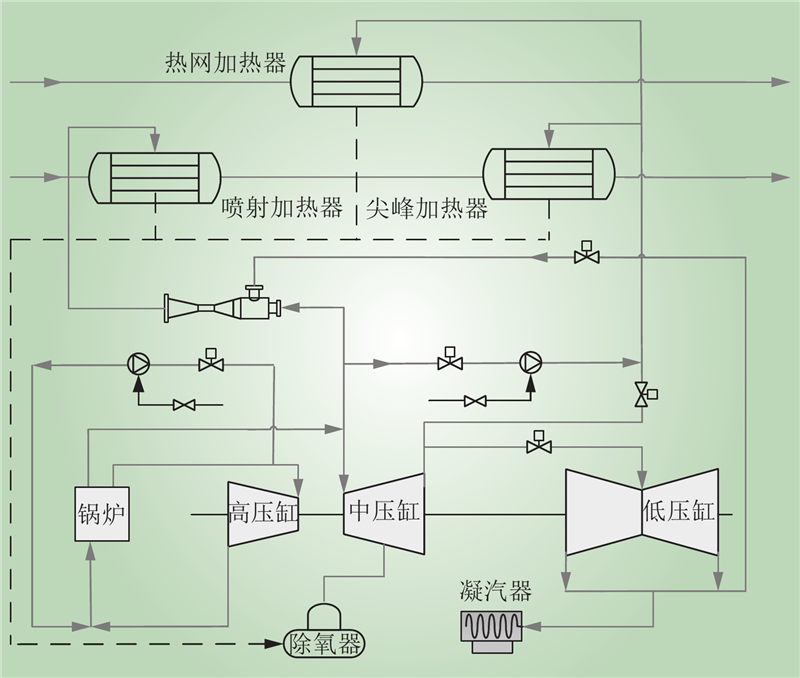

刘畅, 耿林霄, 王珩, 等. 高低旁路联合供热改造控制策略研究[J]. 热力发电, 2020, 49 (11): 126- 132.

|

|

LIU Chang, GENG Linxiao, WANG Heng, et al. Control strategy in transformation of high and low pressure bypass combined heat supply[J]. Thermal Power Generation, 2020, 49 (11): 126- 132.

|

| 11 |

赵金峰, 冯忠宝, 曹丽华, 等. 汽轮机旁路供热系统的减温减压器安全性分析[J]. 汽轮机技术, 2019, 61 (1): 71- 73, 77.

|

|

ZHAO Jinfeng, FENG Zhongbao, CAO Lihua, et al. Safety analysis of desuperheater pressure reducing station in bypass system of steam turbine[J]. Turbine Technology, 2019, 61 (1): 71- 73, 77.

|

| 12 |

王占洲, 曹丽华, 董恩伏, 等. 基于旁路系统提升热电机组风电消纳能力研究[J]. 太阳能学报, 2021, 42 (1): 317- 323.

|

|

WANG Zhanzhou, CAO Lihua, DONG Enfu, et al. Improving wind power accommodation of combined heat and power plant based on bypass system[J]. Acta Energiae Solaris Sinica, 2021, 42 (1): 317- 323.

|

| 13 |

崔锐, 孙建忠, 黄文强. 循环流化床机组在无功率输出时利用高低压旁路供热的应用研究[J]. 山西电力, 2022 (6): 59- 62.

|

|

CUI Rui, SUN Jianzhong, HUANG Wenqiang. Application study on high and low pressure bypass heating in circulating fluidized bed units without power output[J]. Shanxi Electric Power, 2022 (6): 59- 62.

|

| 14 |

宣伟东. 300MW机组高低旁路联合供热改造实践分析[J]. 节能技术, 2020, 38 (6): 561- 564.

|

|

XUAN Weidong. Practical analysis of high and low bypass combined heating system for 300 MW units[J]. Energy Conservation Technology, 2020, 38 (6): 561- 564.

|

| 15 |

魏德, 席新铭, 李健, 等. 耦合喷射器的高背压机组变工况特性研究[J]. 热力发电, 2022, 52 (5): 107- 114.

|

|

WEI De, XI Xinming, LI Jian, et al. Study on off design characteristics of high back pressure unit coupled with ejector[J]. Thermal Power Generation, 2022, 52 (5): 107- 114.

|

| 16 |

刘荣堂, 王宇, 范佩佩, 等. 集成蒸汽喷射器的热电协同系统全工况性能分析[J]. 动力工程学报, 2023, 43 (1): 56- 64.

|

|

LIU Rongtang, WANG Yu, FAN Peipei, et al. Performance analysis of a heat-power synergy system integrated with steam ejectors under the full working condition[J]. Journal of Chinese Society of Power Engineering, 2023, 43 (1): 56- 64.

|

| 17 |

孙博昭, 岳爽, 王春波, 等. 350 MW超临界机组可调式蒸汽喷射器工业供热性能数值模拟研究及试验验证[J]. 华北电力大学学报(自然科学版), 2021, 48 (3): 98- 107.

|

|

SUN Bozhao, YUE Shuang, WANG Chunbo, et al. Numerical simulation and test verification on industrial heating performance of adjustable steam ejector in 350 MW supercritical unit[J]. Journal of North China Electric Power University(Natural Science Edition), 2021, 48 (3): 98- 107.

|

| 18 |

刘聪, 金洁, 胡胜利. 蒸汽喷射器在660 MW超超临界机组真空系统中应用及分析[J]. 汽轮机技术, 2022, 64 (2): 146- 148.

|

|

LIU Cong, JIN Jie, HU Shengli. Application and analysis of steam injector in vacuum system of 660 MW supercritical unit[J]. Turbine Technology, 2022, 64 (2): 146- 148.

|

| 19 |

杨志平, 宋四明, 李维, 等. 耦合喷射器热电联产系统设计及运行优化[J]. 中国电机工程学报, 2020, 40 (9): 2942- 2951.

|

|

YANG Zhiping, SONG Siming, LI Wei, et al. Design and operation optimization of combined heat and power system coupling with ejector[J]. Proceedings of the CSEE, 2020, 40 (9): 2942- 2951.

|

| 20 |

邓庚庚, 周家辉, 周天羽, 等. 新型小汽机耦合多级蒸汽引射器供热系统及性能分析[J]. 动力工程学报, 2023, 43 (2): 222- 230.

|

|

DENG Genggeng, ZHOU Jiahui, ZHOU Tianyu, et al. A new type of coupled multistage steam ejector heating system for small steam turbine and its performance analysis[J]. Journal of Chinese Society of Power Engineering, 2023, 43 (2): 222- 230.

|

| 21 |

王义函, 王华霆, 卢荻, 等. 地热与生物质直燃耦合的热电联产系统热力学性能分析[J]. 动力工程学报, 2022, 42 (7): 677- 685.

|

|

WANG Yihan, WANG Huating, LU Di, et al. Thermodynamic performance analysis of cogeneration system for coupling of geothermal and biomass-fired plant[J]. Journal of Chinese Society of Power Engineering, 2022, 42 (7): 677- 685.

|

| 22 |

周家辉, 邓庚庚, 汪茹康, 等. 配置吸收式热泵的余压梯级利用供热系统优化设计[J]. 动力工程学报, 2023, 43 (2): 165- 173.

|

|

ZHOU Jiahui, DENG Genggeng, WANG Rukang, et al. Optimal design of residual pressure cascade utilization heat supply system with absorption heat pump[J]. Journal of Chinese Society of Power Engineering, 2023, 43 (2): 165- 173.

|

| 23 |

戈志华, 张倩, 熊念, 等. 330MW供热机组低压缸近零出力热力性能分析[J]. 化工进展, 2020, 39 (9): 3650- 3657.

|

|

GE Zhihua, ZHANG Qian, XIONG Nian, et al. Thermal performance analysis of 330MW heating unit with low pressure cylinder near zero output[J]. Chemical Industry and Engineering Progress, 2020, 39 (9): 3650- 3657.

|

| 24 |

李童欣, 赵隆, 刘思雨, 等. ±500 kV直流海底电缆J型管工程化设计与热管理优化[J]. 智慧电力, 2025 (6): 85- 92.

|

|

LI Tongxin, ZHAO Long, LIU Siyu, et al. Engineering design and thermal management optimization of ±500 kV DC submarine cable J-tube[J]. Smart Power, 2025 (6): 85- 92.

|

| 25 |

何东升, 贾志东, 刘让雄, 等. 不同负载率下干式配电变压器绕组热点温升规律及推演模型研究[J]. 智慧电力, 2025, 53 (5): 63- 72.

|

|

HE Dongsheng, JIA Zhidong, LIU Rangxiong, et al. Hotspot temperature rise patterns and deductive model of dry-type distribution transformer windings under different load rates[J]. Smart Power, 2025, 53 (5): 63- 72.

|