| 1 |

HE L G, JING H D, ZHANG Y, et al. Review of thermal management system for battery electric vehicle[J]. Journal of Energy Storage, 2023, 59, 106443.

DOI

|

| 2 |

岳家辉, 夏向阳, 蒋戴宇, 等. 基于电压数据片段混合模型的锂离子电池剩余寿命预测与健康状态估计[J]. 中国电力, 2023, 56 (7): 163- 174.

|

|

YUE Jiahui, XIA Xiangyagn, JIANG Daiyu, et al. Remaining useful life prediction and state of health estimation of lithium-ion batteries based on voltage data segment hybrid model[J]. Electric Power, 2023, 56 (7): 163- 174.

|

| 3 |

黎冲, 王成辉, 王高, 等. 基于数据驱动的锂离子电池健康状态估计技术[J]. 中国电力, 2022, 55 (8): 73- 86, 95.

|

|

LI Chong, WANG Chenghui, WANG Gao, et al. Technology of lithium-ion battery state-of-health assessment based on data-driven[J]. Electric Power, 2022, 55 (8): 73- 86, 95.

|

| 4 |

NA X Y, KANG H F, WANG T, et al. Reverse layered air flow for Li-ion battery thermal management[J]. Applied Thermal Engineering, 2018, 143, 257- 262.

DOI

|

| 5 |

ZHANG F R, LIU P W, HE Y X, et al. Cooling performance optimization of air cooling lithium-ion battery thermal management system based on multiple secondary outlets and baffle[J]. Journal of Energy Storage, 2022, 52, 104678.

DOI

|

| 6 |

JITHIN K V, RAJESH P K. Numerical analysis of single-phase liquid immersion cooling for lithium-ion battery thermal management using different dielectric fluids[J]. International Journal of Heat and Mass Transfer, 2022, 188.

|

| 7 |

YOUSSEF R, HOSEN M S, HE J C, et al. Novel design optimization for passive cooling PCM assisted battery thermal management system in electric vehicles[J]. Case Studies in Thermal Engineering, 2022, 32, 101896.

DOI

|

| 8 |

ZHAO R, GU J J, LIU J. Performance assessment of a passive core cooling design for cylindrical lithium-ion batteries[J]. International Journal of Energy Research, 2018, 42 (8): 2728- 2740.

DOI

|

| 9 |

LUO J, ZOU D Q, WANG Y S, et al. Battery thermal management systems (BTMs) based on phase change material (PCM): a comprehensive review[J]. Chemical Engineering Journal, 2022, 430, 132741.

DOI

|

| 10 |

LIU H Q, JIN C W, LI H, et al. A numerical study of PCM battery thermal management performance enhancement with fin structures[J]. Energy Reports, 2023, 9, 1793- 1802.

DOI

|

| 11 |

贺春敏, 杨翼, 蔡天鏖, 等. 基于Mxene/石蜡CPCM的锂电池热管理系统[J]. 电源技术, 2023, 47 (5): 627- 631.

DOI

|

|

HE Chunmin, YANG Yi, CAI Tian’ao, et al. Thermal management system of lithium ion battery based on Mxene/paraffin composite phase change material[J]. Chinese Journal of Power Sources, 2023, 47 (5): 627- 631.

DOI

|

| 12 |

WANG Y W, PENG P, CAO W J, et al. Experimental study on a novel compact cooling system for cylindrical lithium-ion battery module[J]. Applied Thermal Engineering, 2020, 180, 115772.

DOI

|

| 13 |

XIN Q Q, YANG T Q, ZHANG H Y, et al. Simulation and optimization of lithium-ion battery thermal management system integrating composite phase change material, flat heat pipe and liquid cooling[J]. Batteries, 2023, 9 (6): 334.

DOI

|

| 14 |

SASMITO A P, SHAMIM T, MUJUMDAR A S. Passive thermal management for PEM fuel cell stack under cold weather condition using phase change materials (PCM)[J]. Applied Thermal Engineering, 2013, 58 (1-2): 615- 625.

DOI

|

| 15 |

FANG X Y, NONG X L, LIAO Z R, et al. A novel preheating method for the Li-ion battery using supercooled phase change materials[J]. Science China Technological Sciences, 2023, 66 (1): 193- 203.

DOI

|

| 16 |

WANG Z C, DU C Q, QI R, et al. Experimental study on thermal management of lithium-ion battery with graphite powder based composite phase change materials covering the whole climatic range[J]. Applied Thermal Engineering, 2022, 216, 119072.

DOI

|

| 17 |

CHENG G, WANG Z Z, WANG X Z, et al. All-climate thermal management structure for batteries based on expanded graphite/polymer composite phase change material with a high thermal and electrical conductivity[J]. Applied Energy, 2022, 322, 119509.

DOI

|

| 18 |

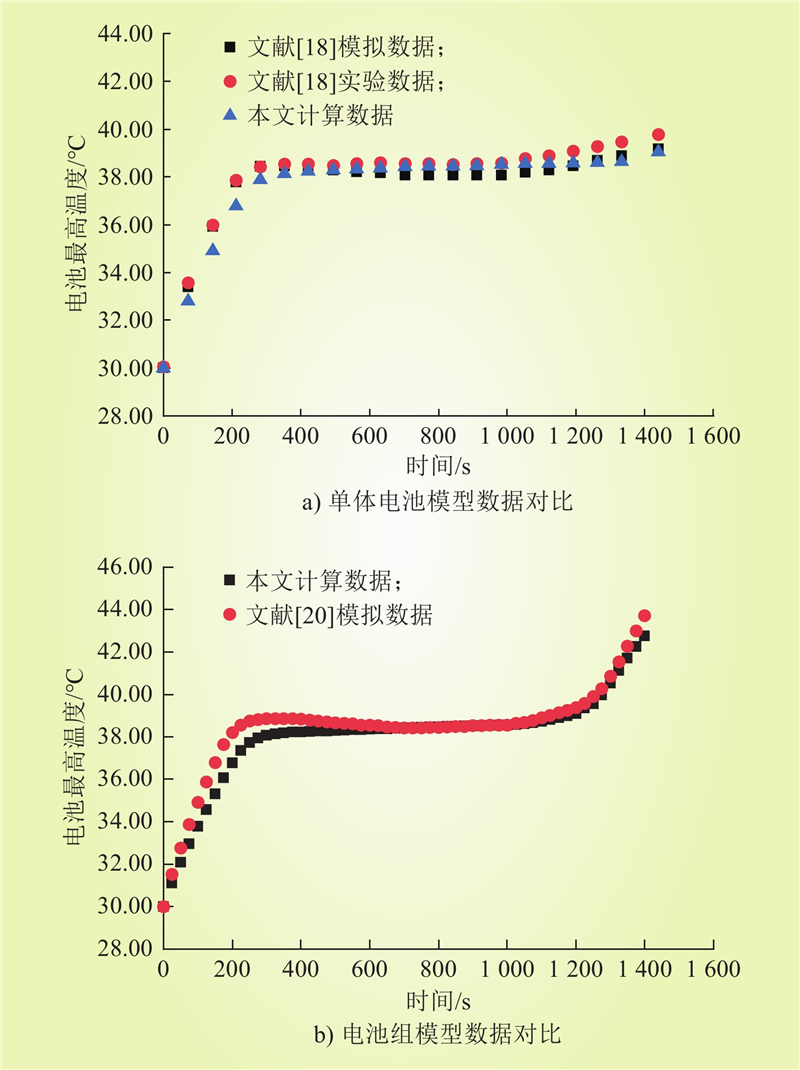

YE Y, SAW L H, SHI Y, et al. Numerical analyses on optimizing a heat pipe thermal management system for lithium-ion batteries during fast charging[J]. Applied Thermal Engineering, 2015, 86, 281- 291.

DOI

|

| 19 |

KANT K, SHUKLA A, SHARMA A, et al. Melting and solidification behaviour of phase change materials with cyclic heating and cooling[J]. Journal of Energy Storage, 2018, 15, 274- 282.

DOI

|

| 20 |

WANG H M, WANG Y F, HU F, et al. Heat generation measurement and thermal management with phase change material based on heat flux for high specific energy power battery[J]. Applied Thermal Engineering, 2021, 194, 117053.

DOI

|

| 21 |

JIAQIANG E, YI F, LI W J, et al. Effect analysis on heat dissipation performance enhancement of a lithium-ion-battery pack with heat pipe for central and southern regions in China[J]. Energy, 2021, 226, 120336.

DOI

|

| 22 |

陈占国. 低温环境锂离子动力电池相变换热研究[D]. 长沙: 湖南大学, 2021.

|

|

CHEN Zhanguo. Study on phase-change heat transfer of low temperature lithium ion power battery[D]. Changsha: Hunan University, 2021.

|

| 23 |

AKBARZADEH M, JAGUEMONT J, KALOGIANNIS T, et al. A novel liquid cooling plate concept for thermal management of lithium-ion batteries in electric vehicles[J]. Energy Conversion and Management, 2021, 231, 113862.

DOI

|

| 24 |

SEDDEGH S, WANG X L, HENDERSON A D. Numerical investigation of heat transfer mechanism in a vertical shell and tube latent heat energy storage system[J]. Applied Thermal Engineering, 2015, 87, 698- 706.

DOI

|

| 25 |

付程阔, 元佳宇, 刘泽宇, 等. 21700锂离子电池风冷结构设计与散热效果研究[J]. 内燃机与配件, 2022, (9): 1- 3.

DOI

|

|

FU Chengkuo, YUAN Jiayu, LIU Zeyu, et al. 21700 Li-ion battery air-cooled structure design and heat dissipation effect research[J]. Internal Combustion Engine & Parts, 2022, (9): 1- 3.

DOI

|

| 26 |

DING Y Z, WEI M X, LIU R. Channel parameters for the temperature distribution of a battery thermal management system with liquid cooling[J]. Applied Thermal Engineering, 2021, 186, 116494.

DOI

|

| 27 |

LI Y H, CHEN Z L, FENG Y, et al. A novel petal-type battery thermal management system with dual phase change materials[J]. International Journal of Heat and Mass Transfer, 2023, 207, 123989.

DOI

|