| 1 |

迟永宁, 梁伟, 张占奎, 等. 大规模海上风电输电与并网关键技术研究综述[J]. 中国电机工程学报, 2016, 36 (14): 3758- 3770.

|

|

CHI Yongning, LIANG Wei, ZHANG Zhankui, et al. An overview on key technologies regarding power transmission and grid integration of large scale offshore wind power[J]. Proceedings of the CSEE, 2016, 36 (14): 3758- 3770.

|

| 2 |

黄碧斌, 张运洲, 王彩霞. 中国 “十四五” 新能源发展研判及需要关注的问题[J]. 中国电力, 2020, 53 (1): 1- 9.

|

|

HUANG Bibin, ZHANG Yunzhou, WANG Caixia. New energy development and issues in China during the 14th five-year plan[J]. Electric Power, 2020, 53 (1): 1- 9.

|

| 3 |

宋冬然, 晏嘉琪, 夏鄂, 等. 基于改进麻雀搜索算法的大型海上风电场电缆布置优化[J]. 电力系统保护与控制, 2022, 50 (12): 134- 143.

|

|

SONG Dongran, YAN Jiaqi, XIA E, et al. Optimization of cable layout for large-scale offshore wind farms based on an improved sparrow search algorithm[J]. Power System Protection and Control, 2022, 50 (12): 134- 143.

|

| 4 |

严新荣, 张宁宁, 马奎超, 等. 我国海上风电发展现状与趋势综述[J]. 发电技术, 2024, 45 (1): 1- 12.

|

|

YAN Xinrong, ZHANG Ningning, MA Kuichao, et al. Overview of current situation and trend of offshore wind power development in China[J]. Power Generation Technology, 2024, 45 (1): 1- 12.

|

| 5 |

林钰, 胡意茹, 李茜, 等. 复杂环境中海底电缆温度场及载流量模型研究[J]. 电子测量与仪器学报, 2021, 35 (11): 39- 46.

|

|

LIN Yu, HU Yiru, LI Qian, et al. Analysis of submarine cable temperature field and ampacity model in complex environment[J]. Journal of Electronic Measurement and Instrumentation, 2021, 35 (11): 39- 46.

|

| 6 |

李萌. 海底电缆载流量计算方法的研究与应用[D]. 北京: 华北电力大学. 2018.

|

|

LI Meng. Research and application of ampacity calculation method of submarine cable[D]. Beijing: North China Electric Power University, 2018.

|

| 7 |

梁永春. 高压电力电缆温度场和载流量评估研究动态[J]. 高电压技术, 2016, 42 (4): 1142- 1150.

|

|

LIANG Yongchun. Technological development in evaluating the temperature and ampacity of power cables[J]. High Voltage Engineering, 2016, 42 (4): 1142- 1150.

|

| 8 |

游磊. 海上风电场送出海缆载流量瓶颈区段与提升方法研究[D]. 广州: 华南理工大学, 2018.

|

|

YOU Lei. Study on the bottleneck section and improvement methods of ampacity of export submarine cable in offshore wind farms[D]. Guangzhou: South China University of Technology, 2018.

|

| 9 |

XIONG L, CHEN Y H, JIAO Y, et al. Study on the effect of cable group laying mode on temperature field distribution and cable ampacity[J]. Energies, 2019, 12 (17): 3397.

DOI

|

| 10 |

刘士利, 罗英楠, 刘宗烨, 等. 基于电磁-热耦合原理的三芯铠装电缆在低频输电方式下的损耗特性研究[J]. 电工技术学报, 2021, 36 (22): 4829- 4836.

|

|

LIU Shili, LUO Yingnan, LIU Zongye, et al. Study on loss characteristics of three core armored cable under low-frequency transmission mode based on electromagnetic, thermal coupling principle[J]. Transactions of China Electrotechnical Society, 2021, 36 (22): 4829- 4836.

|

| 11 |

何旭涛, 马兴端, 闫循平. 降低高压海底电缆登陆段电能损耗的措施研究[J]. 浙江电力, 2011, 30 (10): 29- 31.

DOI

|

|

HE Xutao, MA Xingduan, YAN Xunping. Research on power loss reduction measures for landing parts of high voltage submarine power cables[J]. Zhejiang Electric Power, 2011, 30 (10): 29- 31.

DOI

|

| 12 |

DUTTA S, OVERBYE T J. Optimal wind farm collector system topology design considering total trenching length[J]. IEEE Transactions on Sustainable Energy, 2012, 3 (3): 339- 348.

DOI

|

| 13 |

HOU P, HU W H, CHEN Z. Offshore substation locating in wind farms based on prim algorithm[C]//2015 IEEE Power & Energy Society General Meeting. Denver, CO, USA. IEEE, 2015.

|

| 14 |

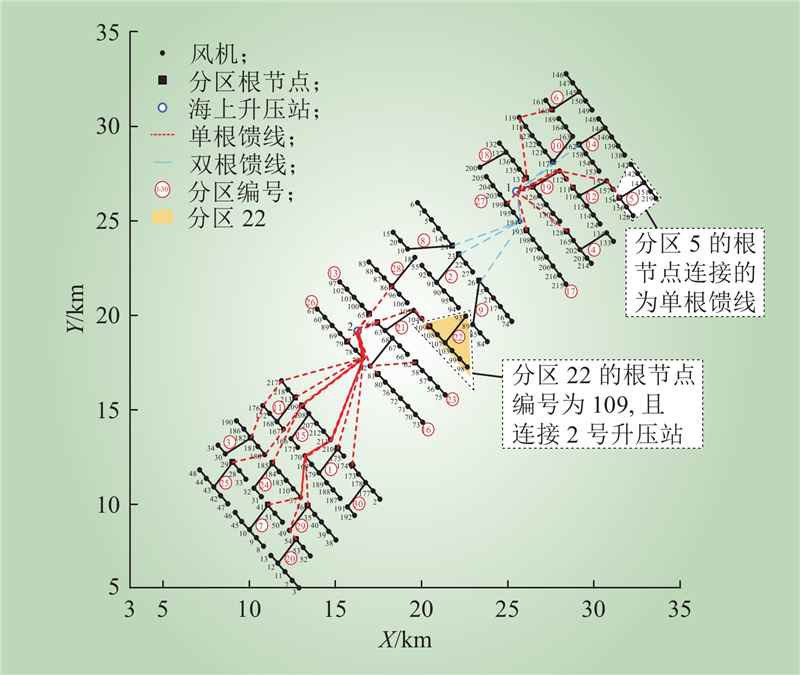

符杨, 吴靖, 魏书荣. 大型海上风电场集电系统拓扑结构优化与规划[J]. 电网技术, 2013, 37 (9): 2553- 2558.

|

|

FU Yang, WU Jing, WEI Shurong. Topology optimization and planning of power collection system for large-scale offshore wind farm[J]. Power System Technology, 2013, 37 (9): 2553- 2558.

|

| 15 |

汪惟源, 乔颖, 窦飞, 等. 基于改进遗传算法的海上风电场集电系统拓扑优化[J]. 中国电力, 2019, 52 (1): 63- 68.

|

|

WANG Weiyuan, QIAO Ying, DOU Fei, et al. Optimization of offshore wind farm collector systems based on improved genetic algorithm[J]. Electric Power, 2019, 52 (1): 63- 68.

|

| 16 |

FISCHETTI M, PISINGER D. Optimizing wind farm cable routing considering power losses[J]. European Journal of Operational Research, 2018, 270 (3): 917- 930.

DOI

|

| 17 |

黄伟, 闫彬禹, 谭茂强, 等. 考虑障碍区影响的海上风电场集电系统拓扑设计[J]. 现代电力, 2018, 35 (1): 6- 13.

|

|

HUANG Wei, YAN Binyu, TAN Maoqiang, et al. Research on optimal design of wind power collection system for offshore wind farms considering the influence of obstacles area[J]. Modern Electric Power, 2018, 35 (1): 6- 13.

|

| 18 |

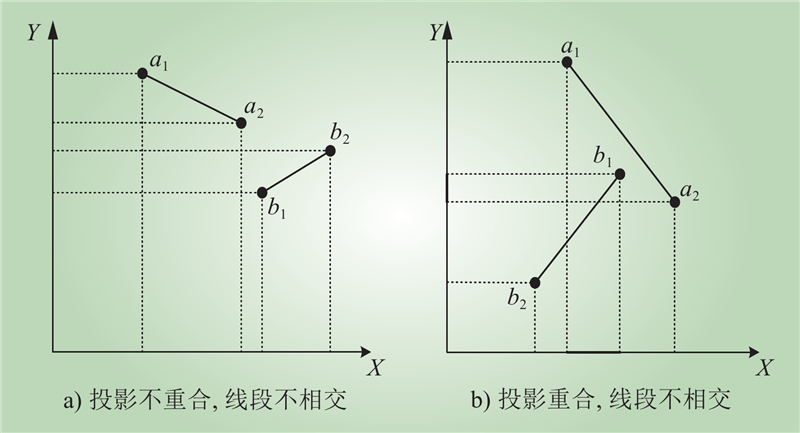

叶婧, 周广浩, 张磊, 等. 考虑馈线交叉规避的海上风电场海缆路径优化[J]. 中国电力, 2023, 56 (6): 167- 175.

|

|

YE Jing, ZHOU Guanghao, ZHANG Lei, et al. Path optimization of submarine cables for offshore wind farm considering feeder crossing avoidance[J]. Electric Power, 2023, 56 (6): 167- 175.

|

| 19 |

JIN R S, HOU P, YANG G Y, et al. Cable routing optimization for offshore wind power plants via wind scenarios considering power loss cost model[J]. Applied Energy, 2019, 254, 113719.

DOI

|

| 20 |

王朝辉, 黄松阁, 林斌, 等. 基于海上风电场区66 kV集电系统海缆最大截面经济性分析[J]. 中国电力, 2023, 56 (11): 20- 28.

|

|

WANG Chaohui, HUANG Songge, LIN Bin, et al. Economic analysis of maximum cross-section of submarine cables for 66 kV offshore wind farm collection systems[J]. Electric Power, 2023, 56 (11): 20- 28.

|

| 21 |

Power cables with extruded insulation and their accessories for rated voltages for 1 kV up to 30 kV: IEC60502-2 [S].

|

| 22 |

CHIPPENDALE R D, PILGRIM J A, GODDARD K F, et al. Analytical thermal rating method for cables installed in J-tubes[J]. IEEE Transactions on Power Delivery, 2017, 32 (4): 1721- 1729.

DOI

|