| 1 |

刘振亚. 特高压电网[M]. 北京: 中国经济出版社, 2005.

|

| 2 |

王胜辉, 王玺铭, 董兴浩, 等. 特高压直流输电线路极间搭接塑料薄膜的放电模拟试验[J]. 中国电力, 2022, 55 (6): 103- 110.

|

|

WANG Shenghui, WANG Ximing, DONG Xinghao, et al. Simulation experiment on discharge of plastic film overlapping on UHVDC transmission lines[J]. Electric Power, 2022, 55 (6): 103- 110.

|

| 3 |

张广洲. 高压直流输电工程电磁环境研究[D]. 武汉: 华中科技大学, 2006.

|

|

ZHANG Guangzhou. Study on EM environment of HVDC transmission projects[D]. Wuhan: Huazhong University of Science and Technology, 2006.

|

| 4 |

张广洲, 邬雄, 路遥, 等. 直流输电工程电磁环境研究[R]. 武汉: 武汉高压研究所, 2006.

|

| 5 |

邬雄, 万保权. 输变电工程的电磁环境[M]. 北京: 中国电力出版社, 2009.

|

| 6 |

邬雄, 张广洲, 刘云鹏. 输电线路电晕及电晕效应[M]. 北京: 中国电力出版社, 2017.

|

| 7 |

《输变电设施的电场、磁场及其环境影响》编写组. 输变电设施的电场、磁场及其环境影响[M]. 北京: 中国电力出版社, 2007.

|

| 8 |

周建国. 工频电场磁场与健康[M]. 上海: 复旦大学出版社, 2011.

|

| 9 |

WHO. 环境健康准则: 极低频场[R]. 《环境健康准则: 极低频场》译审委员会, 译. 北京: 中国标准出版社, 2015.

|

| 10 |

干喆渊, 邬雄, 张广洲, 等. ±500 kV直流输电系统电磁环境调查研究[J]. 高电压技术, 2006, 32 (9): 146- 148, 152.

|

|

GAN Zheyuan, WU Xiong, ZHANG Guangzhou, et al. Research on the EM environment of HVDC transmission system[J]. High Voltage Engineering, 2006, 32 (9): 146- 148, 152.

|

| 11 |

张广洲. 交直流线路混合电场计算与测试研究[D]. 武汉: 武汉大学, 2012.

|

|

ZHANG Guangzhou. Calculation and measurement of hybrid electric field from AC/DC lines[D]. Wuhan: Wuhan University, 2012.

|

| 12 |

张业茂, 张建功, 张广洲, 等. 基于nRF905模块的无线通信直流电场测量系统设计[J]. 高电压技术, 2012, 38 (11): 2869- 2874.

|

|

ZHANG Yemao, ZHANG Jiangong, ZHANG Guangzhou, et al. Design of DC electric field measurement system with wireless communication based on nRF905 module[J]. High Voltage Engineering, 2012, 38 (11): 2869- 2874.

|

| 13 |

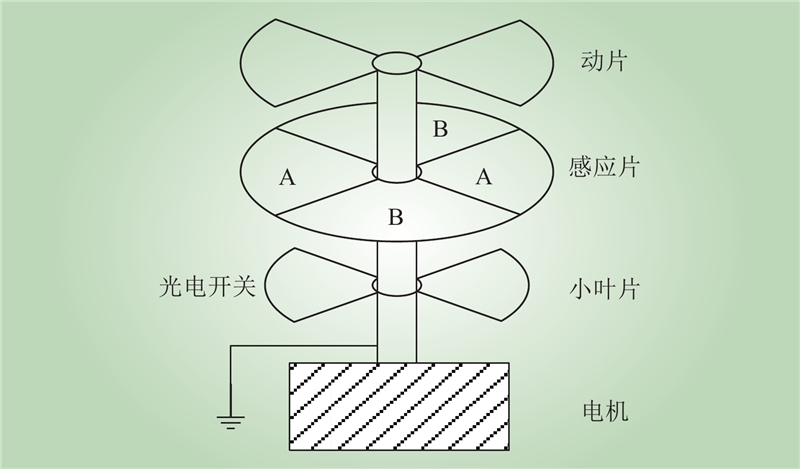

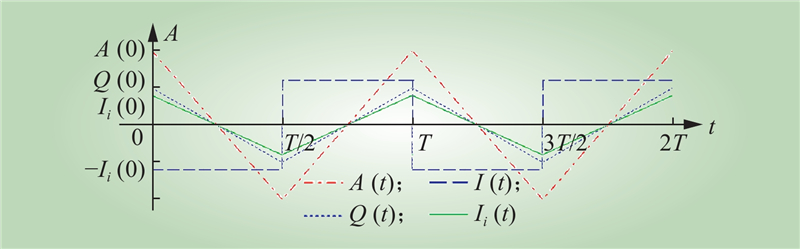

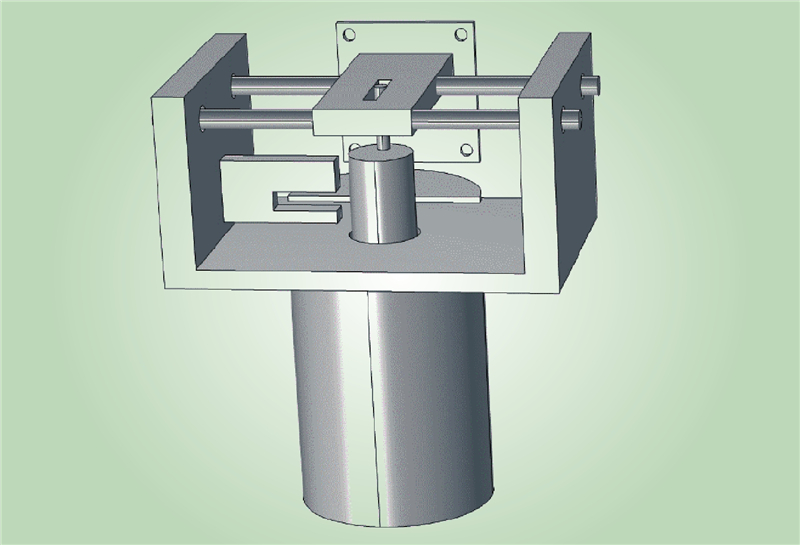

张洪钏, 袁海文, 陆家榆, 等. 交直流混合电场旋转式一体化测试仪的研制[J]. 电网技术, 2012, 36 (12): 182- 188.

|

|

ZHANG Hongchuan, YUAN Haiwen, LU Jiayu, et al. Development of an integrative rotary test instrument for AC/DC hybrid electric field[J]. Power System Technology, 2012, 36 (12): 182- 188.

|

| 14 |

汤林. 光纤应变测量系统设计[D]. 南京: 南京航空航天大学, 2006.

|

|

TANG Lin. Design of a strain measurement system based on a fiber optical interferer sensor[D]. Nanjing: Nanjing University of Aeronautics and Astronautics, 2006.

|

| 15 |

MARUVADA P S. Corona performance of high-voltage transmission lines[M]. Baldock: Research Studies Press, 2000.

|

| 16 |

张贵新、朱萍萍. 基于Pockels电光效应原理的电压传感器[C]//中国电机工程学会高压专委会2007年年会学术论文集, 2007.

|

|

ZHANG Guixin, ZHU Pingping. Voltage sensor based on Pockels electro-optic effect principle[C]// Academic Proceedings of 2007 Annual Meeting of High Voltage Special Committee of China Society of Electrical Engineering, 2007.

|

| 17 |

FORT A, MUGNAINI M, VIGNOLI V, et al. Design, modeling, and test of a system for atmospheric electric field measurement[J]. IEEE Transactions on Instrumentation and Measurement, 2011, 60 (8): 2778- 2785.

|

| 18 |

陈新安, 刘肃, 黄庆安. 硅-硅直接键合制造静电感应器件[J]. 电力电子技术, 2004, 38 (2): 92- 94.

|

|

CHEN Xinan, LIU Su, HUANG Qingan. Static induction device manufactured by silicon direct bonding[J]. Power Electronics, 2004, 38 (2): 92- 94.

|

| 19 |

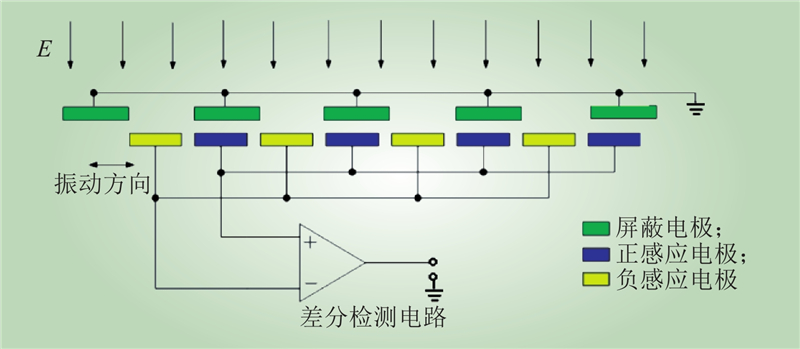

杨鹏飞, 彭春荣, 张海岩, 等. SOI微型电场传感器的设计与测试[J]. 电子与信息学报, 2011, 33 (11): 2771- 2774.

|

|

YANG Pengfei, PENG Chunrong, ZHANG Haiyan, et al. Design and testing of a SOI electric-field microsensor[J]. Journal of Electronics & Information Technology, 2011, 33 (11): 2771- 2774.

|

| 20 |

BAHREYNI B, WIJEWEERA G, SHAFAI C, et al. Analysis and design of a micromachined electric-field sensor[J]. Journal of Microelectromechanical Systems, 2008, 17 (1): 31- 36.

|

| 21 |

RIEHL P S, SCOTT K L, MULLER R S, et al. Electrostatic charge and field sensors based on micromechanical resonators[J]. Journal of Microelectromechanical Systems, 2003, 12 (5): 577- 589.

|

| 22 |

李炎新, 石立华, 高成, 等. 用宽带模拟量光纤传输系统测量脉冲电磁场[J]. 高电压技术, 2006, 32 (2): 34- 36.

|

|

LI Yanxin, SHI Lihua, GAO Cheng, et al. Measurement of pulse electromagnetic field using wide band fiber optic analogue transmission system[J]. High Voltage Engineering, 2006, 32 (2): 34- 36.

|

| 23 |

孔旭, 谢彦召. 基于光纤技术的电磁脉冲3维电、磁场测量系统[J]. 高电压技术, 2015, 41 (1): 339- 345.

|

|

KONG Xu, XIE Yanzhao. Electric field and magnetic field measuring system for EMP measurement based on fiber technology[J]. High Voltage Engineering, 2015, 41 (1): 339- 345.

|

| 24 |

王益成. 电光效应光纤电压传感器及其在高电压测量中的应用[J]. 高电压技术, 1990, 16 (3): 46- 48.

|

|

WANG Yicheng. Fiber–optic voltage sensors for electro–optic effect and its application in high voltage test[J]. High Voltage Engineering, 1990, 16 (3): 46- 48.

|

| 25 |

迟焕新. 测量瞬态电场的自由电位球形传感器[J]. 高电压技术, 1985, 11 (2): 74- 80.

|

|

CHI Huanxin. Free potential spherical sensor for measuring transient electric field[J]. High Voltage Engineering, 1985, 11 (2): 74- 80.

|

| 26 |

WINN W P, BYERLEY L G. Electric field growth in thunderclouds[J]. Quarterly Journal of the Royal Meteorological Society, 1975, 101 (430): 979- 994.

|

| 27 |

LUNDBERG K H, SHAFRAN J S, KUANG J, et al. A self-resonant MEMS-based electrostatic field sensor[C]//2006 American Control Conference. Minneapolis, MN, USA. IEEE, 2006: 6.

|

| 28 |

VOSTEEN R E. DC electrostatic voltmeters and fieldmeters[C]//Conference Record of Ninth Annual Meeting of the IEEE Industrial Applications Society. October, 1974.

|

| 29 |

唐立军, 周年荣, 方正云, 等. 基于MEMS电场传感器的直流验电器系统设计[J]. 传感器与微系统, 2019, 38 (9): 77- 80.

|

|

TANG Lijun, ZHOU Nianrong, FANG Zhengyun, et al. Design of DC electroscope system based on MEMS electric-field sensor[J]. Transducer and Microsystem Technologies, 2019, 38 (9): 77- 80.

|

| 30 |

闻小龙, 杨鹏飞, 储昭志, 等. 基于MEMS的距离自适应型非接触静电仪[J]. 电子与信息学报, 2021, 43 (10): 3068- 3074.

|

|

WEN Xiaolong, YANG Pengfei, CHU Zhaozhi, et al. A daptive-distance noncontact electrostatic meter based on MEMS technology[J]. Journal of Electronics & Information Technology, 2021, 43 (10): 3068- 3074.

|

| 31 |

MARUVADA P S, DALLAIRE R D, PEDNEAULT R. Development of field-mill instruments for ground-level and above-ground electric field measurement under HVDC transmission lines[C]//IEEE Transactions on Power Apparatus and Systems. IEEE, 2007: 738–744.

|

| 32 |

TANT P. Design and application of a field mill as a high-voltage DC meter[C]//2006 IEEE Instrumentation and Measurement Technology Conference Proceedings. Sorrento. IEEE, 2006: 1861–1866.

|