| 1 |

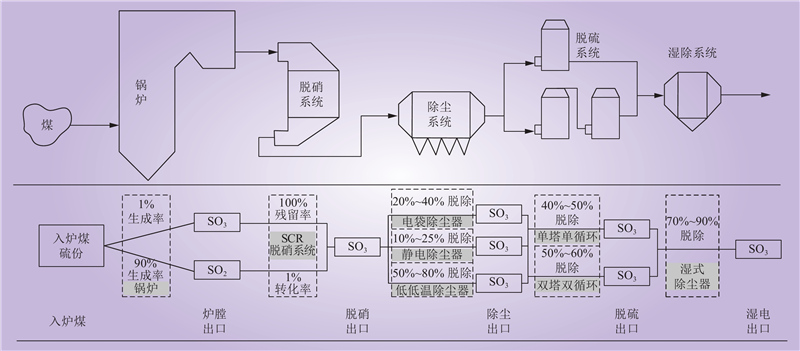

朱法华. 燃煤电厂烟气污染物超低排放技术路线的选择[J]. 中国电力, 2017, 50 (3): 11- 16.

|

|

ZHU Fahua. Methodologies on choosing appropriate technical route for ultra low emission of flue gas pollutants from coal-fired power plants[J]. Electric Power, 2017, 50 (3): 11- 16.

|

| 2 |

SRIVASTAVA R K, MILLER C A, ERICKSON C, et al. Emissions of sulfur trioxide from coal-fired power plants[J]. Journal of the Air & Waste Management Association (1995), 2004, 54(6): 750–762.

|

| 3 |

ZHENG C H, WANG Y F, LIU Y, et al. Formation, transformation, measurement, and control of SO3 in coal-fired power plants[J]. Fuel, 2019, 241, 327- 346.

DOI

|

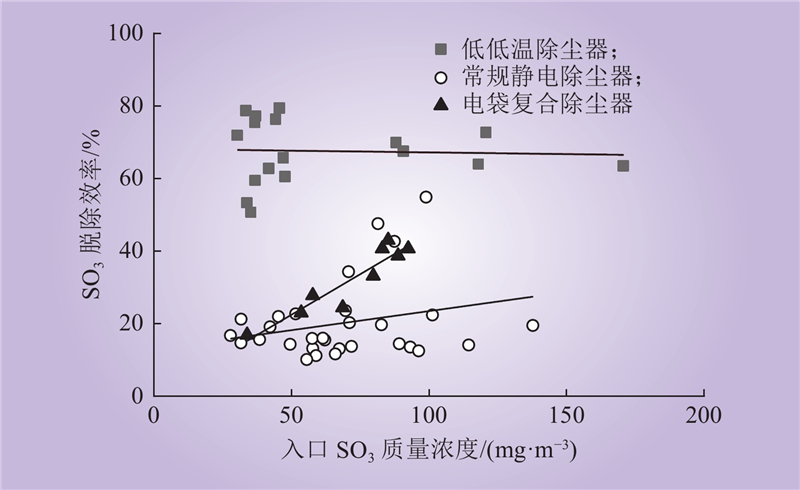

| 4 |

YANG Z, ZHENG C, ZHANG X, et al. Challenge of SO3 removal by wet electrostatic precipitator under simulated flue gas with high SO3 concentration[J]. Fuel, 2018, 217, 597- 604.

DOI

|

| 5 |

张杨, 冯前伟, 杨用龙, 等. 燃煤电厂烟气SO3排放控制研究进展[J]. 中国电机工程学报, 2021, 41 (1): 231- 248.

|

|

ZHANG Yang, FENG Qianwei, YANG Yonglong, et al. A review on SO3 emission control of coal-fired power plant[J]. Proceedings of the CSEE, 2021, 41 (1): 231- 248.

|

| 6 |

XIAO H P, QI C, CHENG Q Y, et al. Experimental and modeling studies of SO3 homogeneous formation in the post-flame region[J]. Aerosol and Air Quality Research, 2018, 18 (12): 2939- 2947.

DOI

|

| 7 |

SHANTHAKUMAR S, SINGH D N, PHADKE R C. Flue gas conditioning for reducing suspended particulate matter from thermal power stations[J]. Progress in Energy and Combustion Science, 2008, 34 (6): 685- 695.

DOI

|

| 8 |

HUANG J Y, WANG H M, SHI Y J, et al. Performance of a pilot-scale wet electrostatic precipitator for the control of sulfuric acid mist[J]. Environmental Science and Pollution Research, 2016, 23 (19): 19219- 19228.

DOI

|

| 9 |

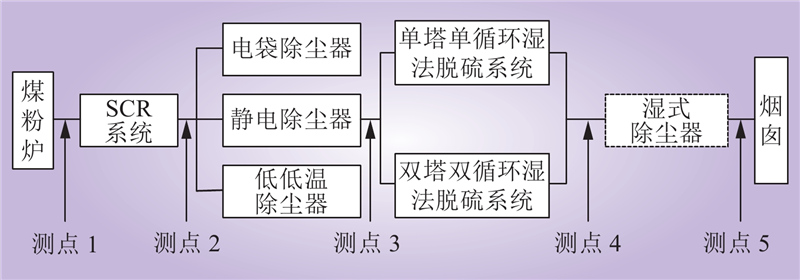

杨用龙, 苏秋凤, 张杨, 等. 燃煤电站典型超低排放工艺的SO3脱除性能及排放特性[J]. 中国电机工程学报, 2019, 39 (10): 2962- 2970.

|

|

YANG Yonglong, SU Qiufeng, ZHANG Yang, et al. Removal performance and emission characteristics of SO3 by typical ultra-low emission technologies in coal-fired power plants[J]. Proceedings of the CSEE, 2019, 39 (10): 2962- 2970.

|

| 10 |

潘丹萍, 吴昊, 鲍静静, 等. 电厂湿法脱硫系统对烟气中细颗粒物及SO3酸雾脱除作用研究[J]. 中国电机工程学报, 2016, 36 (16): 4356- 4362, 4519.

|

|

PAN Danping, WU Hao, BAO Jingjing, et al. Removal effect of wet flue gas desulfurization system on fine particles and SO3 acid mist from coal-fired power plants[J]. Proceedings of the CSEE, 2016, 36 (16): 4356- 4362, 4519.

|

| 11 |

潘丹萍, 吴昊, 黄荣廷, 等. 石灰石-石膏法烟气脱硫过程中SO3酸雾脱除特性[J]. 东南大学学报(自然科学版), 2016, 46 (2): 311- 316.

|

|

PAN Danping, WU Hao, HUANG Rongting, et al. Removal properties of sulfuric acid mist during limestone-gypsum flue gas desulfurization process[J]. Journal of Southeast University (Natural Science Edition), 2016, 46 (2): 311- 316.

|

| 12 |

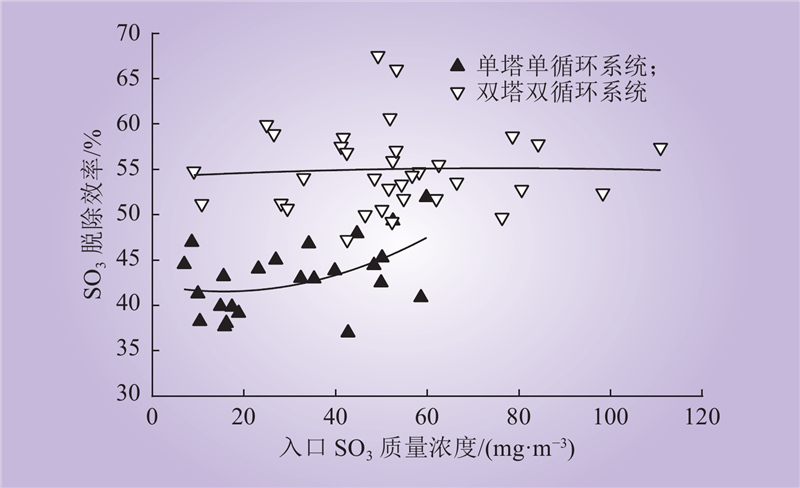

朱愉洁, 杨学宝, 张健翔, 等. 双塔双循环湿法脱硫系统SO3脱除率及排放测试[J]. 电力科技与环保, 2022, 38 (3): 245- 250.

|

|

ZHU Yujie, YANG Xuebao, ZHANG Jianxiang, et al. SO3 removal rate and emission test of double towers double-cycle wet flue gas desulfurization system[J]. Electric Power Technology and Environmental Protection, 2022, 38 (3): 245- 250.

|

| 13 |

曹御风, 姚宇平, 刘含笑, 等. 低低温电除尘器粉尘及SO3协同去除研究[J]. 中国电力, 2017, 50 (9): 121- 124.

|

|

CAO Yufeng, YAO Yuping, LIU Hanxiao, et al. The in-depth research on PM and SO3 simultaneous removal by low-low temperature ESP technique[J]. Electric Power, 2017, 50 (9): 121- 124.

|

| 14 |

李小龙, 李军状, 段玖祥, 等. 燃煤电厂烟气中SO3协同控制情况及排放现状[J]. 中国电力, 2019, 52 (10): 155- 161.

|

|

LI Xiaolong, LI Junzhuang, DUAN Jiuxiang, et al. SO3 cooperative control and emission situation in the flue gas of coal-fired power plant[J]. Electric Power, 2019, 52 (10): 155- 161.

|

| 15 |

杜振, 杨立强, 魏宏鸽, 等. 低低温电除尘器对粉尘特性和SO3脱除效果影响分析[J]. 中国电力, 2017, 50 (9): 125- 128.

|

|

DU Zhen, YANG Liqiang, WEI Hongge, et al. Analysis on the impacts of low-low temperature eletrostatic precipitator on dust characteristics and SO3 removal effect[J]. Electric Power, 2017, 50 (9): 125- 128.

|

| 16 |

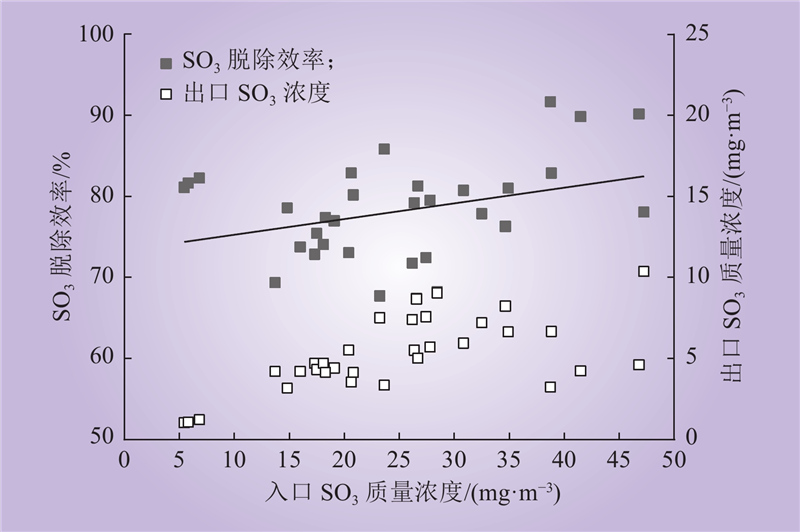

雒飞, 胡斌, 吴昊, 等. 湿式电除尘对PM2.5/SO3酸雾脱除特性的试验研究[J]. 东南大学学报(自然科学版), 2017, 47 (1): 91- 97.

|

|

LUO Fei, HU Bin, WU Hao, et al. Experimental study on removal properties of PM2.5 and sulfuric acid mist by wet electrostatic precipitator[J]. Journal of Southeast University (Natural Science Edition), 2017, 47 (1): 91- 97.

|

| 17 |

王贵华, 朱斌帅, 张海珍, 等. 湿式电除尘器SO3、HCl、HF脱除效率试验研究[J]. 中国电力, 2018, 51 (12): 170- 174.

|

|

WANG Guihua, ZHU Binshuai, ZHANG Haizhen, et al. Experimental study on SO3, HCl and HF removal efficiency of wet electrostatic precipitator[J]. Electric Power, 2018, 51 (12): 170- 174.

|

| 18 |

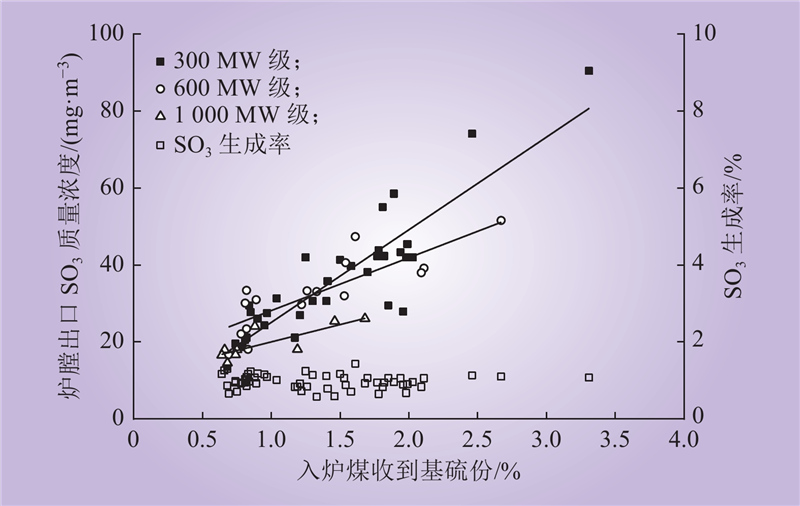

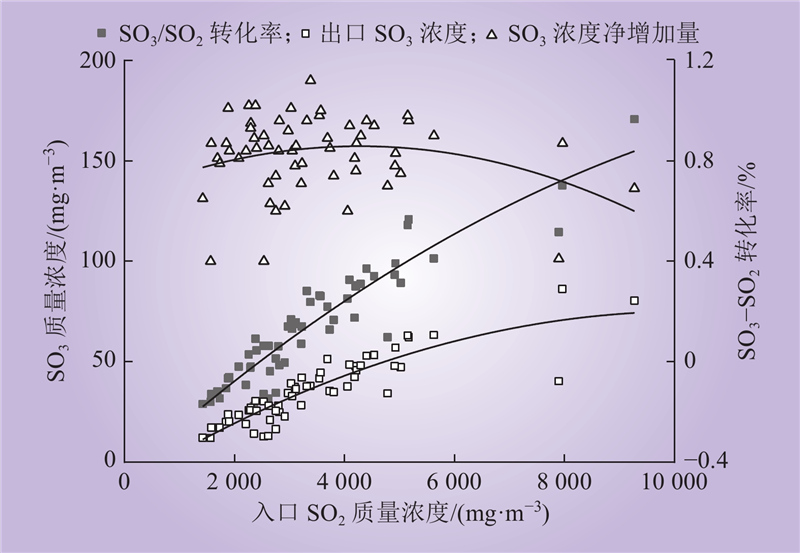

李高磊, 郭沂权, 张世博, 等. 超低排放燃煤电厂SO3生成及控制的试验研究[J]. 中国电机工程学报, 2019, 39 (4): 1079- 1085.

|

|

LI Gaolei, GUO Yiquan, ZHANG Shibo, et al. Experimental research on SO3 generation and control in ultra-low emission coal-fired power plant[J]. Proceedings of the CSEE, 2019, 39 (4): 1079- 1085.

|

| 19 |

杜振, 王丰吉, 刘强, 等. 湿式除尘器多种污染物协同脱除效果分析[J]. 环境工程, 2018, 36 (5): 100- 103.

|

|

DU Zhen, WANG Fengji, LIU Qiang, et al. Analysis on synergistic removal of multiple pollutants in wet electrostatic precipitators[J]. Environmental Engineering, 2018, 36 (5): 100- 103.

|

| 20 |

固定污染源排气中颗粒物测定与气态污染物采样方法: GB/T16157—1996[S]. 北京: 中国标准出版社, 1996.

|

| 21 |

MORETTI A. Advanced emissions control technologies for coal-fired power plants[R]. BR-1886, Bangkok, Thailand: Power-Gen Asia, 2012.

|

| 22 |

KIM K H, CHOI J S. Kinetics and mechanism of the oxidation of sulfur dioxide on. alpha. -Fe2O3[J]. The Journal of Physical Chemistry, 1981, 85(17): 2447–2450.

|

| 23 |

TAN Y W, CROISET E, DOUGLAS M A, et al. Combustion characteristics of coal in a mixture of oxygen and recycled flue gas[J]. Fuel, 2006, 85 (4): 507- 512.

DOI

|

| 24 |

WANG X P, LIU X W, LI D, et al. Effect of steam and sulfur dioxide on sulfur trioxide formation during oxy-fuel combustion[J]. International Journal of Greenhouse Gas Control, 2015, 43, 1- 9.

DOI

|

| 25 |

XIANG B X, SHEN W F, ZHANG M, et al. Effects of different factors on sulfur trioxide formations in a coal-fired circulating fluidized bed boiler[J]. Chemical Engineering Science, 2017, 172, 262- 277.

DOI

|

| 26 |

SCHOFIELD K. The kinetic nature of sulfur’s chemistry in flames[J]. Combustion and Flame, 2001, 124 (1/2): 137- 155.

|

| 27 |

杜振, 朱文韬, 张杨, 等. SCR脱硝催化剂全寿命周期性能变化规律研究[J]. 中国电机工程学报, 2022, 42 (16): 5996- 6004.

|

|

DU Zhen, ZHU Wentao, ZHANG Yang, et al. Study on life cycle performance change of SCR denitration catalyst[J]. Proceedings of the CSEE, 2022, 42 (16): 5996- 6004.

|

| 28 |

赵海宝, 郦建国, 何毓忠, 等. 低低温电除尘关键技术研究与应用[J]. 中国电力, 2014, 47 (10): 117- 121, 147.

|

|

ZHAO Haibao, LI Jianguo, HE Yuzhong, et al. Research and application on low-low temperature electrostatic precipitator technology[J]. Electric Power, 2014, 47 (10): 117- 121, 147.

|

| 29 |

陈奎续. 电袋复合除尘器协同脱除Hg及SO3[J]. 环境工程学报, 2017, 11 (11): 5937- 5942.

|

|

CHEN Kuixu. Removal of mercury and sulfur trioxide by electrostatic-fabric integrated precipitator[J]. Chinese Journal of Environmental Engineering, 2017, 11 (11): 5937- 5942.

|